2025 Ultimate Guide: How to Choose the Right Bleach Pump for Your Needs

When it comes to selecting the right bleach pump for your specific needs in 2025, making an informed decision is crucial. According to a recent market analysis by the Chemical Pumping Association, the demand for bleach pumps is projected to rise by over 15% in the coming years, driven primarily by the increased necessity for disinfection in various industries. This surge in demand emphasizes the importance of understanding the features and specifications that differentiate one bleach pump from another.

Expert in the field of chemical processing, Dr. Emily Carter, has noted, “Choosing the right bleach pump is more than just a purchasing decision; it’s about ensuring safety, efficiency, and reliability in your operations.” This insight highlights the essential factors that need to be considered, such as flow rates, materials of construction, and the specific application environment. By carefully evaluating these parameters, you can not only enhance operational efficiency but also ensure compliance with safety regulations. As we delve into this ultimate guide, we aim to equip you with the knowledge necessary to make the best choice for your bleach pump needs, thus navigating the complexities of this essential equipment with confidence.

Key Factors to Consider When Selecting a Bleach Pump for Your System

When selecting the right bleach pump for your system, several key factors must be taken into consideration to ensure optimal performance and safety. According to a report by the Chemical Pump Institute, nearly 70% of operational issues in chemical handling systems stem from improper pump selection. This underscores the importance of assessing your specific needs, such as the flow rate and pressure requirements of your system. For instance, if your application demands a consistent flow rate of 10 gallons per minute with a discharge pressure of 30 psi, you should ensure the pump you select meets or exceeds these specifications.

Another critical factor is the compatibility of the pump materials with bleach solutions. As highlighted in a study by the American Water Works Association, certain materials can deteriorate when exposed to sodium hypochlorite, leading to potential leaks and system failure. Selecting a pump made from materials like PVDF or PVC, which are resistant to corrosive substances, can significantly enhance the longevity and reliability of your setup. Furthermore, consider the pump's maintenance requirements; models designed for easy disassembly can reduce downtime and repair costs, making them a more economical choice in the long run.

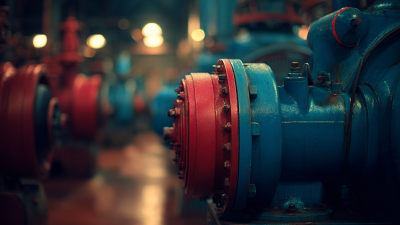

Comparing Different Types of Bleach Pumps: Pros and Cons

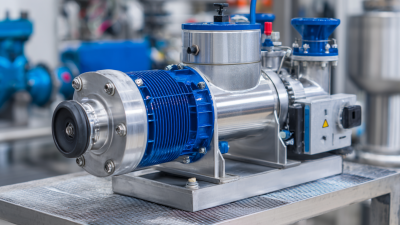

When choosing a bleach pump, it's essential to understand the various types available and their respective advantages and disadvantages. One popular category is the diaphragm pump, which is lauded for its reliability and ability to handle corrosive substances like bleach with ease. According to a report by MarketsandMarkets, the diaphragm pump market is expected to grow significantly, reaching an estimated $3.4 billion by 2025. This growth highlights the rising demand for pumps that can effectively handle challenging chemicals while maintaining efficiency.

On the other hand, peristaltic pumps provide a unique advantage with their design, allowing for minimal risk of contamination. They are especially suitable for applications requiring high purity, as the fluid only contacts the tubing. However, one drawback is their relatively higher operational cost compared to diaphragm pumps. A survey by IPSOS shown that 72% of industrial operators value ease of maintenance and operational efficiency over initial cost, which can influence their choice between these pump types. Balancing the pros and cons based on specific needs is crucial for making an informed investment in a bleach pump.

Essential Features to Look for in a High-Quality Bleach Pump

When selecting a bleach pump, understanding essential features is crucial to ensure efficiency and longevity. One of the most critical components is the pump's material, as bleach can be corrosive. High-quality pumps often use materials such as polypropylene or PVDF, which are noted for their chemical resistance. According to a recent industry report, pumps made from these materials have a significantly lower failure rate, improving both maintenance costs and operational lifespan.

Another vital feature is the flow rate and pressure capability. It's important to choose a pump that matches your specific application needs. For instance, a study published by the American Society of Plumbing Engineers indicates that pumps with adjustable flow rates provide greater flexibility and can serve a variety of applications, from industrial to residential use. Additionally, look for features such as easy installation and maintenance access, which can drastically reduce downtime, according to data from the Pump and Pumping Equipment Manufacturers Association, highlighting the cost-effectiveness of user-friendly designs.

Maintenance Tips to Extend the Life of Your Bleach Pump

Proper maintenance is crucial for extending the life of your bleach pump, ensuring it operates efficiently and reliably. Regularly inspecting the pump for leaks and corrosion is a foundational step. Consider setting a schedule for routine checks, ideally every few months, to catch any potential issues early. Clean the pump’s inlet and outlet filters to prevent clogging, which can hinder performance and lead to wear and tear on the pump components.

Additionally, it’s vital to keep an eye on the chemical concentration of the bleach you’re using. High concentrations can damage seals and internal parts, so dilute as recommended. Ensure that all moving parts are well-lubricated and replace worn-out components proactively, as this can be a cost-effective way to extend the overall lifespan of your pump. Lastly, always consult the manufacturer's guidelines for specific maintenance instructions tailored to your pump model, which can provide invaluable insights for upkeep.

2025 Ultimate Guide: How to Choose the Right Bleach Pump for Your Needs - Maintenance Tips to Extend the Life of Your Bleach Pump

| Pump Type | Flow Rate (GPH) | Max Distance (ft) | Material | Weight (lbs) | Maintenance Frequency |

|---|---|---|---|---|---|

| Diaphragm Pump | 20 | 50 | PVC | 10 | Monthly |

| Peristaltic Pump | 15 | 30 | Rubber | 12 | Quarterly |

| Electric Pump | 25 | 75 | Stainless Steel | 15 | Weekly |

| Vacuum Pump | 10 | 20 | Aluminum | 8 | Bi-Annual |

Top Brands and Models of Bleach Pumps in 2025: A Comprehensive Review

In 2025, choosing the right bleach pump is crucial for a range of applications, from swimming pool maintenance to industrial cleaning. The market is brimming with options, making it essential to focus on the top brands and models that stand out in terms of reliability and performance. Notable names such as Vanguard Pumps and ChemMaster have gained a reputation for their innovative technologies and durable construction. Vanguard's latest model features advanced automation and user-friendly controls, ensuring optimal dosing accuracy, while ChemMaster offers a sleek design that prioritizes safety and ease of maintenance.

In addition to these established brands, emerging companies like EcoClean Solutions have introduced eco-friendly bleach pumps that cater to environmentally conscious consumers. Their models are not only efficient but also utilize sustainable materials, making them a strong choice for those looking to reduce their ecological footprint. Furthermore, models like the AquaPro 3000 have been highlighted for their versatility, capable of handling various bleach concentrations without compromising performance. Overall, 2025 is set to offer a diverse selection of bleach pumps, ensuring that users can find the perfect model suited to their specific needs.

Related Posts

-

Understanding the Importance of Bleach Pumps in Industrial Cleaning Processes

-

Maximize Your Pond's Health: Expert Insights on Fountain Pump Efficiency and Eco-Friendly Choices

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

Exploring Innovative Chemical Pump Alternatives for Industrial Applications

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

The Ultimate Guide to Choosing the Right Electric Pumps for Your Home and Garden