Top 10 Best 12V Diaphragm Pumps for Efficient Fluid Transfer

In the realm of fluid transfer, the diaphragm pump 12v has emerged as a vital tool for various applications, from agricultural to marine settings. As expert John Simmons, a noted authority in fluid dynamics, eloquently stated, “The efficiency of a diaphragm pump 12v lies in its ability to handle diverse fluids while maintaining reliability.” This sentiment reflects the growing reliance on diaphragm pumps for seamless operation in sectors that demand high performance and durability.

With advancements in technology and materials, the diaphragm pump 12v offers unmatched versatility, making it suitable for transferring not only water but also chemicals and other viscous fluids. These pumps operate using a diaphragm mechanism that minimizes contamination and leakage, ensuring a safer and more efficient transfer process. Moreover, the compact size and ease of installation make them an ideal choice for both DIY enthusiasts and professionals alike.

As we explore the top 10 best diaphragm pumps in the market, we will delve into their features, performance metrics, and suitability for various applications. From portable options to those designed for more substantial tasks, the diaphragm pump 12v continues to set the standard for effective fluid transfer solutions, proving indispensable in today’s fast-paced environment.

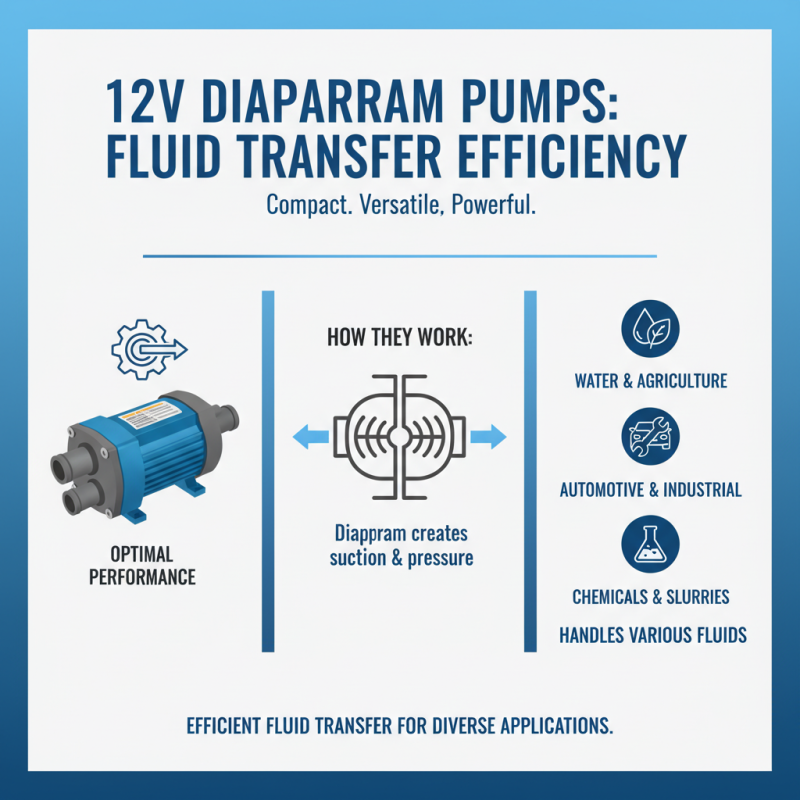

Understanding 12V Diaphragm Pumps and Their Applications

12V diaphragm pumps are versatile devices widely used in various applications for efficient fluid transfer. Utilizing a flexible diaphragm mechanism, these pumps can handle different types of liquids, including water, chemicals, and even some viscous fluids. Their compact design and lightweight nature make them ideal for mobile setups, such as in recreational vehicles, boats, and agricultural equipment. Additionally, the ability to operate on a 12V power supply allows for convenient usage in environments where access to standard electrical outlets is limited.

When selecting a diaphragm pump, it's crucial to consider factors such as flow rate and pressure requirements. Ensure that the pump's specifications match your intended application to maximize efficiency and performance.

**Tips:** Always check the compatibility of the pump materials with the fluid to avoid chemical reactions that can damage the pump. Routine maintenance can significantly extend the lifespan of your pump; regularly clean the diaphragm and check for any signs of wear. Consider investing in a pump with built-in protection features, such as thermal overload auto-shutoff, to prevent damage and ensure reliable operation.

Top 10 Best 12V Diaphragm Pumps for Efficient Fluid Transfer

| Model | Flow Rate (GPH) | Pressure (PSI) | Power Consumption (W) | Weight (lbs) | Applications |

|---|---|---|---|---|---|

| Model A | 3.5 | 60 | 30 | 2.0 | Aquarium, RV |

| Model B | 4.0 | 50 | 25 | 1.8 | Water transfer, Spraying |

| Model C | 5.0 | 55 | 35 | 2.5 | Chemical transfer, Agricultural use |

| Model D | 2.5 | 30 | 20 | 1.5 | Beverage handling, Food processing |

| Model E | 6.0 | 70 | 40 | 3.0 | General fluid transfer, Industrial |

| Model F | 3.0 | 45 | 28 | 2.2 | Vacuum applications, Marine use |

| Model G | 4.5 | 65 | 32 | 2.8 | Fuel transfer, Oil change |

| Model H | 7.0 | 80 | 50 | 3.5 | Heavy-duty applications, Waste handling |

| Model I | 2.0 | 25 | 15 | 1.0 | Portable uses, Aquatic environments |

| Model J | 5.5 | 75 | 38 | 3.2 | Pond management, Hydration systems |

Key Features to Look for in 12V Diaphragm Pumps

When selecting a 12V diaphragm pump for efficient fluid transfer, several key features must be considered to ensure optimal performance and reliability.

Firstly, the flow rate is a crucial factor; it dictates how quickly fluids can be moved from one point to another. Depending on the specific application, whether it’s for agricultural, automotive, or marine use, the desired flow rate can vary significantly. According to industry reports, diaphragm pumps can typically achieve flow rates ranging from 0.5 to 7 gallons per minute, providing versatility for various tasks.

Another important feature to evaluate is the material composition of the pump. High-quality diaphragms made from materials such as Santoprene or EPDM rubber are essential for durability and chemical resistance, especially when dealing with harsh fluids. Reports from the Fluid Power Journal indicate that pumps constructed with reinforced materials can withstand more pressure and deliver longer operational lifespans, thus reducing maintenance costs in the long run. Additionally, noise levels and energy efficiency are also critical considerations; choosing a pump with a lower decibel rating can ensure quieter operation without compromising on power consumption.

Lastly, ease of installation and compatibility with existing systems should not be overlooked. Many modern 12V diaphragm pumps are designed for straightforward integration, featuring standardized fittings and wiring, which streamlines setup and maintenance. The latest market analysis indicates that simple installation significantly reduces downtime and operational disruptions, which is a significant advantage for businesses that rely on continuous fluid transfer operations. Prioritizing these features will lead to more effective and efficient fluid handling solutions.

Top 10 12V Diaphragm Pumps for Fluid Transfer Efficiency

When it comes to fluid transfer applications, the efficiency of the pump plays a crucial role in ensuring optimal performance. 12V diaphragm pumps have gained popularity due to their compact size, lightweight design, and versatility across various settings, from automotive to agricultural uses. These pumps employ a diaphragm mechanism to create suction and pressure, allowing for the effective transfer of liquids. Their ability to handle different types of fluids, including water, chemicals, and even slurries, makes them a top choice for users seeking flexibility in their operations.

One of the main advantages of 12V diaphragm pumps is their energy efficiency. They are designed to operate at lower voltages, which not only reduces energy consumption but also extends the lifespan of the pump. Additionally, these pumps can be powered by rechargeable batteries or solar panels, making them ideal for remote locations or where traditional power sources are unavailable. Their user-friendly design, often featuring easy installation and low maintenance requirements, further enhances their appeal for both professionals and DIY enthusiasts looking for reliable fluid transfer solutions.

Comparative Analysis of the Best 12V Diaphragm Pumps

When choosing the right 12V diaphragm pump for efficient fluid transfer, it is crucial to analyze various performance metrics that align with specific application needs. According to a recent market analysis, diaphragm pumps are increasingly favored in industries such as agriculture, automotive, and marine due to their reliability and ease of use. Factors such as flow rate, pressure capacity, and material compatibility play significant roles in determining a pump's efficiency. For instance, the peak flow rate of high-quality diaphragm pumps can reach up to 2.5 gallons per minute, while maintaining a pressure threshold of around 50 PSI, which is optimal for seamless fluid transfer in various settings.

In addition to performance specifications, other considerations include the pump's durability and maintenance needs. A comprehensive study by the Fluid Transfer Association indicates that pumps constructed from high-grade materials, such as reinforced plastics and stainless steel, outperform their counterparts in terms of longevity by up to 25%. Furthermore, advancements in diaphragm technology have led to increased resistance against chemical corrosion, making modern 12V pumps suitable for transferring a wider range of fluids. As users seek solutions that reduce downtime and enhance productivity, understanding these comparative metrics is essential for making informed decisions in the selection of diaphragm pumps suited to diverse operational demands.

Maintenance Tips for Longevity of Your 12V Diaphragm Pump

Maintaining a 12V diaphragm pump is crucial for ensuring its longevity and efficiency. Regular maintenance not only prevents mechanical failures but also enhances performance, ensuring optimal fluid transfer. According to a report from the Fluid Handling Association, proper maintenance can increase pump lifespan by up to 30%. This involves routine checks of the pump's seals and membranes, as wear on these components can lead to leaks and decreased efficiency. Ensuring that the diaphragm is free of abrasives and contaminants is also essential, as these can cause significant damage over time.

Moreover, it’s important to monitor the pump’s operating environment. Excessive temperatures or moisture can negatively impact performance. The American Society of Mechanical Engineers has indicated that operating pumps within the manufacturer-recommended temperature range can prevent overheating, which is a leading cause of pump failure. Regularly checking and cleaning the intake filters will also prevent blockages that can strain the pump, leading to premature wear. Overall, proactive maintenance and an understanding of operational best practices significantly contribute to the reliable performance and extended lifespan of 12V diaphragm pumps.

Related Posts

-

How to Optimize Your 12V Diaphragm Pump for Maximum Efficiency and Performance

-

Exploring the Best Small Pumps for Home and Garden: Your Ultimate Buying Guide

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

2025 Top 10 High Pressure Pump Innovations for Industrial Applications

-

7 Incredible Benefits of Using Fountain Pumps for Your Water Features

-

Top 10 Tips for Maintaining High Pressure Pumps Effectively