2026 Best 2 Diaphragm Pumps for All Your Needs?

In recent years, the demand for versatile pumping solutions has surged. The global diaphragm pump market is expected to reach approximately $3 billion by 2026, highlighting the importance of finding the best options available. This growth is driven by the increasing need for reliable fluid transfer across various industries. The "2 diaphragm pump" stands out as a popular choice due to its efficiency and adaptability.

A significant advantage of diaphragm pumps is their ability to handle a wide range of fluids. With low maintenance needs and ease of operation, these pumps are crucial in sectors like chemical processing and food production. Reports indicate that diaphragm pumps can handle solids, slurries, and viscous liquids effectively. Users often report difficulties in choosing the right pump, causing them to overlook key features. This reflects a need for better education on selecting a "2 diaphragm pump" that suits specific needs.

Looking forward, the importance of selecting the right diaphragm pump cannot be overstated. As industries evolve, the demand for reliable, high-performance pumps will only increase. Understanding the available options is crucial for efficiency and productivity. Choosing wisely now can prevent costly mistakes in the future.

Overview of Diaphragm Pumps and Their Applications

Diaphragm pumps offer versatile solutions across various industries. These pumps are designed to handle both liquids and gases. They consist of a flexible diaphragm that separates the pump chamber. As the diaphragm moves, it creates a changing volume. This process enables the pump to draw in and expel fluids effectively. According to a recent industry report, the global diaphragm pump market was valued at approximately $2 billion in 2022. It is projected to grow at a CAGR of 4.3% through 2030.

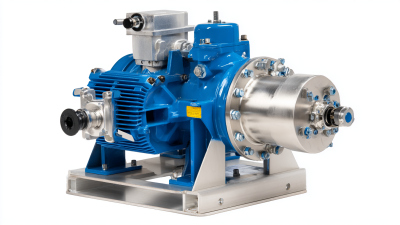

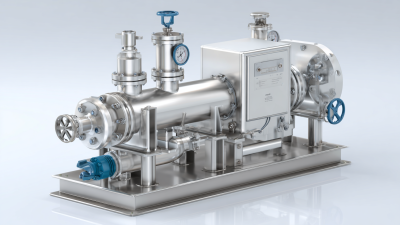

These pumps find applications in multiple sectors, including chemical processing, food and beverage, and pharmaceuticals. For example, in the chemical industry, diaphragm pumps handle corrosive fluids with ease. They ensure safe operation while minimizing leakage risks. In the food and beverage sector, they are invaluable for transferring ingredients without contamination. A study highlighted that over 40% of manufacturers prefer diaphragm pumps for their reliability and efficiency.

However, not all diaphragm pumps are created equal. Some models may struggle with high-viscosity fluids or pulsation issues. In harsh environments, wear and tear can affect performance over time. Understanding these limitations is essential for optimal pump selection. Adapting to specific operational needs will enhance efficiency. Choosing the right diaphragm pump requires careful consideration of application requirements.

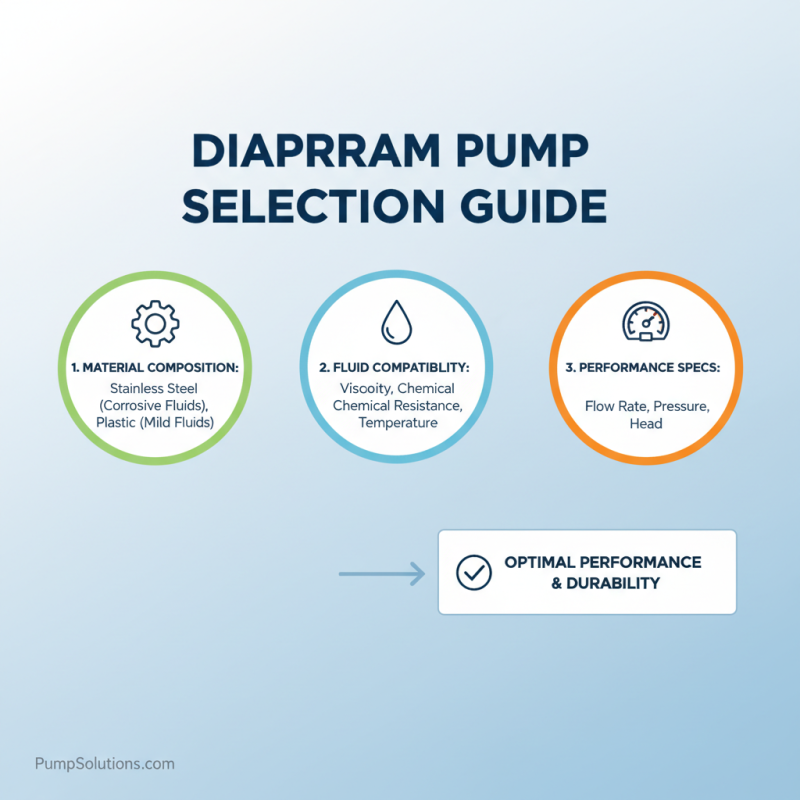

Key Features to Consider When Selecting a Diaphragm Pump

When selecting a diaphragm pump, understanding the key features is crucial. Look for the pump's material composition. Different materials affect durability and compatibility with various fluids. A stainless steel pump may work better with corrosive substances. Meanwhile, plastic pumps might suit less aggressive applications.

Consider the pump's flow rate. It impacts how quickly you can move fluids. Higher flow rates can be tempting, but they may not be necessary for every task. Sometimes, a lower flow rate provides more control over sensitive liquids. Also, check the diaphragm design. Some pumps have reinforced diaphragms, ensuring longer life and better performance under stress.

It's vital to reflect on your specific needs. Analyze your pumping environment. Will the pump face harsh conditions? How about the required pressure? These factors influence pump selection significantly. Do not overlook the importance of efficiency. An energy-efficient pump can save costs over time, even if the initial investment seems higher. Each choice has trade-offs. Think about the long-term implications of your decision.

Top Picks for 2026: Best Diaphragm Pumps Reviewed

When it comes to diaphragm pumps, versatility is key. These pumps can handle various fluids and applications, from industrial to agricultural use. The best options for 2026 feature improved materials and designs, enhancing their durability and efficiency. Customers especially appreciate reliability, yet many admit to being overwhelmed by choices.

Consider a pump that effectively manages fluid viscosity. A model that excels in high-pressure applications can significantly improve performance. Users often highlight noise levels as a concern. It's surprising how a pump's sound can influence daily operations. Some might overlook this factor during selection, only to realize its importance later.

Maintenance is another challenging aspect. Simple designs often require less frequent servicing. However, some owners find performance declines due to neglect. A pump that needs regular checks can impact productivity. It's crucial to reflect on these elements to ensure long-term satisfaction. Before making a final decision, weigh your specific needs against the options available.

2026 Best Diaphragm Pumps Performance Comparison

This bar chart compares the performance ratings of the top diaphragm pumps of 2026. Each pump is rated from 1 to 10 based on efficiency, durability, and user satisfaction.

Comparison of Performance and Efficiency in Leading Models

When looking for diaphragm pumps in 2026, performance and efficiency become crucial. Recent industry data indicates that the best models offer a flow rate ranging from 2 to 50 gallons per minute. This capacity aligns well with most industrial applications. However, only a few models achieve optimal efficiency, often reaching around 80% or higher in ideal conditions.

Efficiency can be impacted by various factors, such as fluid viscosity and operational temperature. Sometimes, high-performance pumps fail under certain conditions, leading to unexpected downtimes. In a study conducted in 2023, approximately 30% of users reported decreased efficiency due to incorrect pump selection. This highlights the importance of understanding specific needs before making a choice.

In terms of material construction, pumps made from composite or stainless steel tend to offer better longevity. However, they may be more costly upfront. Less durable pumps could save money initially, but they often require more frequent replacements. Data shows that users who invest in quality pumps experience a significant reduction in long-term operational costs.

Maintaining and Troubleshooting Your Diaphragm Pump

When it comes to diaphragm pumps, maintenance is crucial. Regular checks can prevent costly breakdowns. Research indicates that 30% of pump failures occur due to inadequate maintenance. Users often overlook small issues that can escalate. Regularly inspecting seals and diaphragms can save time and money. Early detection of wear can extend the pump's lifespan.

Troubleshooting is part of the process. If the pump is not delivering the expected flow rate, check for blockages. A simple obstruction can cause significant performance issues. Inadequate air pressure might also lead to inefficiency. According to industry surveys, over 25% of users experience airflow issues. Misalignment and loose connections should also be addressed promptly.

Training your team on common issues is essential. They should know how to identify problems early. Documentation of maintenance activities matters. Reports from 2022 show that proper record-keeping can boost pump efficiency by 15%. Encourage a culture of vigilance. The little details make the biggest impact.

Related Posts

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

How to Optimize Your 12V Diaphragm Pump for Maximum Efficiency and Performance

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications