10 Best High Pressure Pumps for Efficient Fluid Transfer in 2023

In the realm of industrial operations and fluid transfer, the significance of high pressure pumps cannot be overstated. These powerful devices are engineered to facilitate the movement of liquids and gases under high-pressure conditions, ensuring efficiency and reliability in various applications. From agricultural irrigation systems to oil and gas extraction, the ability to transfer fluids with precision and speed is essential for maintaining productivity and safety in the workplace.

As we delve into the year 2023, the demand for high pressure pumps continues to rise, driven by advancements in technology and the growing need for effective fluid management solutions. Choosing the right high pressure pump can make a significant difference in operational efficiency, energy consumption, and overall performance. This article will explore the ten best high pressure pumps available this year, highlighting their features, benefits, and applications to assist users in making informed decisions that suit their specific needs.

Understanding the diverse array of high pressure pumps on the market is crucial for anyone involved in the fluid transfer industry. Whether you are seeking enhanced performance for a hydraulic system or require high pressure solutions for cleaning and maintenance tasks, our comprehensive review will provide valuable insights and guide you toward the most efficient options for your fluid transfer challenges in 2023.

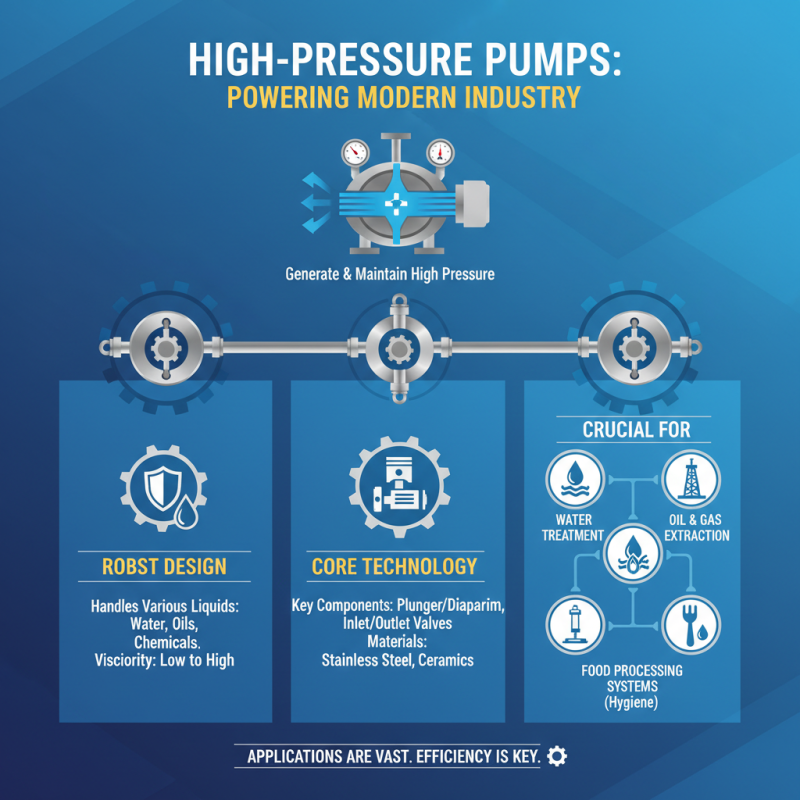

Overview of High Pressure Pumps and Their Applications

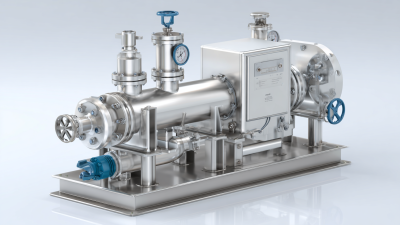

High pressure pumps play a crucial role in various industries by facilitating efficient fluid transfer, which is essential for a wide range of applications. These pumps are designed to generate and maintain high pressures, allowing them to move fluids effectively through pipelines, systems, and machinery. Their robust construction and advanced technology make them suitable for handling liquids with varying viscosities, including water, oils, and chemicals. Common applications include water treatment, oil and gas extraction, hydraulic systems, and even food processing, where cleanliness and efficiency are paramount.

The versatility of high pressure pumps extends to their ability to function in demanding environments. In industrial settings, these pumps are utilized for tasks such as surface cleaning, equipment cooling, and chemical injection, where precision and reliability are required. Additionally, they are employed in the construction industry for concrete pumping and spraying, showcasing their importance in enabling the seamless execution of significant projects. The ability to customize these pumps for specific tasks further enhances their appeal, making them indispensable tools in achieving optimal fluid transfer performance across diverse sectors.

Key Features to Look for in High Pressure Pumps

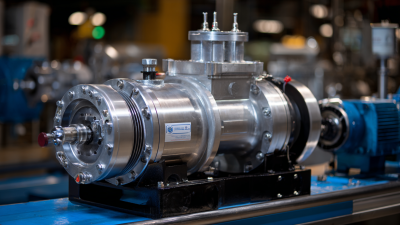

When selecting high-pressure pumps for efficient fluid transfer, several key features should be considered to ensure optimal performance and longevity. Firstly, pump material and construction play a crucial role. High-pressure applications often involve corrosive or abrasive fluids, so choosing pumps made from durable materials like stainless steel or specialized alloys can significantly enhance their lifespan. Additionally, the pump's sealing technology should be robust to prevent leaks and maintain pressure integrity.

Another important aspect is the pump's flow rate and pressure rating. Understanding the specific requirements of the application will help in selecting a pump that can deliver the desired performance. High-pressure pumps should ideally have adjustable flow rates to accommodate varying operational needs. Furthermore, energy efficiency is a significant consideration; pumps that are designed with advanced motor technology can reduce operational costs while maintaining performance. Attention to these features will help ensure that the selected pump meets both efficiency standards and operational demands.

Top 10 High Pressure Pumps for Fluid Transfer in 2023

When selecting a high-pressure pump for fluid transfer in 2023, it's crucial to consider various factors that influence efficiency and performance. High-pressure pumps are essential in industries ranging from agriculture to manufacturing, as they facilitate the rapid and effective movement of liquids. Key attributes to look for include flow rate, pressure capabilities, and compatibility with the fluids being transferred. The best models boast durability and reliability, ensuring they can withstand the rigors of demanding applications.

In addition to performance specifications, energy efficiency and ease of maintenance are also important considerations when choosing a high-pressure pump. Many modern pumps are designed with improved technology that minimizes energy consumption while maximizing output. Moreover, features such as quick-release connections and self-priming capabilities contribute to efficient operation and reduced downtime. By focusing on these critical elements, you can select a high-pressure pump that delivers optimal results, enhancing fluid transfer processes across various applications.

Comparative Analysis of Performance and Price for Each Pump

When selecting high pressure pumps for efficient fluid transfer, it is crucial to conduct a comparative analysis of their performance and price. The market offers a diverse range of pumps, each with unique specifications and capabilities. Factors such as flow rate, pressure output, and energy efficiency should be evaluated alongside their price points. High-pressure pumps that balance impressive performance metrics with competitive pricing are particularly sought after in various industries, from agriculture to manufacturing.

In addition to performance specifications, it's important to consider the long-term value a pump provides. Some pumps may have a higher initial cost but offer better durability and maintenance services, leading to lower operational costs over time. Others may be budget-friendly but may require more frequent repairs or replacements, ultimately impacting project budgets. Analyzing the total cost of ownership, including energy consumption and maintenance requirements, can provide deeper insights into which pumps offer the best efficiency and value for investment in 2023.

Maintenance Tips to Ensure Longevity of High Pressure Pumps

Proper maintenance of high-pressure pumps is essential for ensuring their longevity and optimal performance. Regular inspection and cleaning are crucial steps in the maintenance routine. Operators should check for any signs of wear, leaks, or unusual noises that may indicate issues. Additionally, keeping the pump and its surroundings clean prevents the accumulation of dirt and debris that can impede performance. It’s also advisable to inspect the hoses and fittings for any signs of damage, as these components are vital for efficient fluid transfer.

Another key aspect of maintenance is monitoring the pump’s operating conditions. Ensuring that the pump is used within its designed pressure and flow specifications can significantly extend its lifespan. Regular lubrication of moving parts reduces friction and wear, contributing to smoother operation. Furthermore, maintaining a consistent schedule for oil changes and filter replacements helps to ensure that the internal components remain in good condition. Implementing these maintenance practices will not only enhance the efficiency of high-pressure pumps but also significantly reduce the likelihood of costly repairs.

10 Best High Pressure Pumps for Efficient Fluid Transfer in 2023

This chart illustrates the maximum pressure capabilities of the top 10 high pressure pumps for efficient fluid transfer in 2023. Maintaining proper usage and care can extend the longevity of these pumps significantly.

Related Posts

-

How to Optimize Efficiency with High Pressure Pump Selection

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

What is a High Pressure Pump and How Does it Work Efficiently

-

2025 Top 10 High Pressure Pump Innovations for Industrial Applications

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance