2025 How to Choose the Best 12 Volt Sprayer Pump for Your Needs

Choosing the right 12 volt sprayer pump can be a daunting task, especially with the variety of options available on the market today. Whether you are using it for agricultural purposes, lawn maintenance, or other applications, understanding your specific needs is crucial for making the best choice. A 12 volt sprayer pump offers versatility and convenience, allowing users to transport and operate their equipment with ease. The right pump can make a significant difference in efficiency and effectiveness when it comes to spraying liquids.

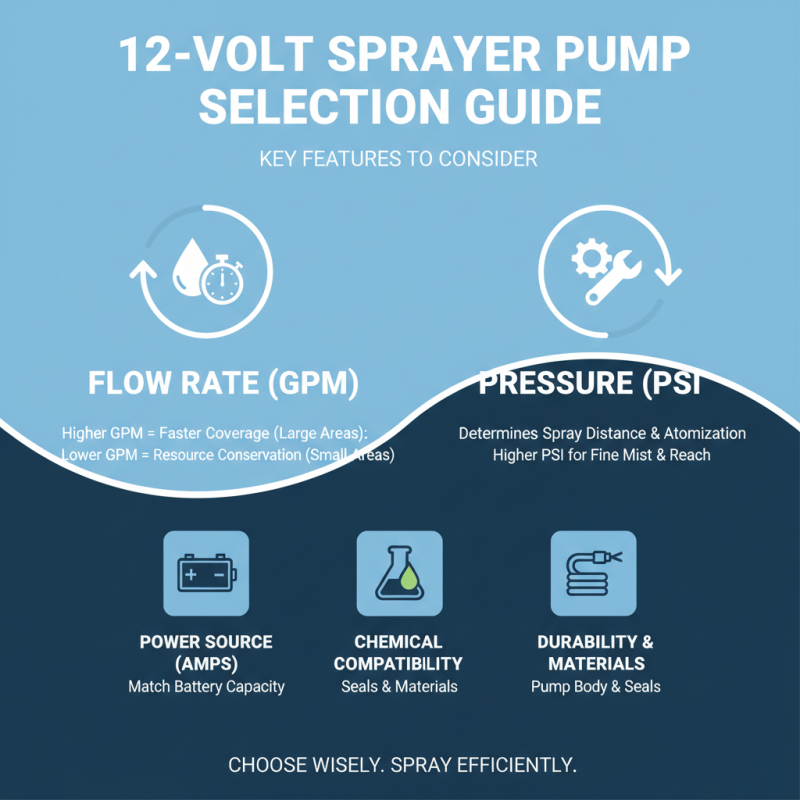

In this guide, we will explore essential factors to consider when selecting the best 12 volt sprayer pump for your needs. From flow rate and pressure to compatibility with different spraying systems, we’ll break down the key features that can help you make an informed decision. Additionally, we will cover how to assess the size, durability, and maintenance requirements of various pumps, ensuring you select one that fits your specific application and environment. Armed with this knowledge, you’ll be equipped to find a sprayer pump that not only meets your expectations but also enhances your spraying experience.

Understanding the Types of 12 Volt Sprayer Pumps Available

When selecting a 12 Volt sprayer pump, it’s essential to understand the various types available to ensure it meets your specific needs. Typically, sprayer pumps fall into three main categories: diaphragm pumps, gear pumps, and piston pumps. Diaphragm pumps are renowned for their ability to handle many types of liquids, including corrosive ones, making them popular for agricultural and landscaping applications. According to industry data, diaphragm pumps can achieve flow rates up to 3.5 GPM, giving them the edge for versatility.

Gear pumps are another option, primarily suited for delivering low-viscosity liquids. They are known for their ability to maintain constant flow despite pressure fluctuations. Research indicates that gear pumps typically offer flow rates ranging from 1 to 3 GPM, highlighting their reliability in consistent and efficient performance. On the other hand, piston pumps are ideal for applications requiring high pressure, suitable for tasks such as tree spraying or agricultural pest control. These pumps can produce working pressures up to 150 PSI, making them favorable for more demanding jobs.

**Tips:** When choosing a pump, always assess the fluid type you intend to use and the corresponding flow rate required for your tasks. Additionally, consider the power source and ensure your vehicle can support the pump's demands. Maintenance is also key; regularly check seals and filters to prolong the lifespan of your sprayer pump and improve overall performance.

Key Features to Consider When Selecting a 12 Volt Sprayer Pump

When selecting a 12 Volt sprayer pump, several key features should be taken into account to ensure it meets your specific needs. First and foremost, consider the pump's flow rate, which is measured in gallons per minute (GPM). A higher GPM will cover larger areas more quickly, making it ideal for extensive gardening or agricultural tasks. Conversely, if your projects are smaller, a lower flow rate can still be efficient and help in conserving resources.

Another critical feature to evaluate is the pressure range of the sprayer pump, typically measured in psi (pounds per square inch). A pump with adjustable pressure settings allows you to tailor application intensity based on the type of chemicals or fertilizers you are using. For instance, delicate plants may require lower pressure to avoid damage, while larger areas might benefit from higher pressures for thorough coverage.

**Tips:** When choosing a sprayer pump, think about the terrain you’ll be working on. If you are dealing with uneven or rough landscapes, look for models that offer versatility and durability. Additionally, consider the ease of maintenance; pumps with replaceable parts or those that are easy to clean can save you time and effort in the long run. Finally, check for features such as compatibility with different types of spraying attachments, which can greatly enhance the flexibility of your pump for various applications.

Assessing the Performance and Efficiency of Sprayer Pumps

When selecting a 12-volt sprayer pump, assessing performance and efficiency is crucial for optimizing agricultural productivity. With the global agricultural sprayer market projected to reach $5.8 billion by 2025, understanding the nuances of pump performance can greatly impact operational efficiency. Key performance metrics include flow rate, pressure output, and power consumption, all of which can vary significantly among different models.

According to recent industry reports, a pump with a flow rate of 1.8 gallons per minute (GPM) is often ideal for small to mid-sized operations, striking a balance between adequate coverage and minimal electricity consumption.

Efficiency is determined not only by these performance metrics but also by the technology utilized within the pump. Data from the Agricultural Engineering Journal indicates that diaphragm pumps tend to offer higher efficiency rates, particularly at varying pressure levels. Additionally, the pump's duty cycle—measuring how long it can operate continuously without overheating—plays a vital role in selecting the right sprayer for specific needs. Continuous operation capacity typically ranges from 30% to 100% depending on design and application, thus influencing the longevity and reliability of the equipment in real-world farming scenarios. By carefully evaluating these factors, users can make informed decisions that boost both the efficiency and effectiveness of their spraying operations.

Evaluating Compatibility with Existing Equipment and Accessories

When choosing the best 12-volt sprayer pump, evaluating its compatibility with your existing equipment and accessories is crucial to ensure optimal performance and functionality. First and foremost, consider the type of sprayer setup you currently have. Verify the connections and fittings of your current hoses, tanks, and nozzles, as compatibility can greatly affect the pump's efficiency. A pump that seamlessly integrates with your existing tools will reduce the risk of leaks and mechanical issues, allowing for a smoother operation during spraying tasks.

In addition to physical connections, it’s essential to assess the pump's pressure and flow rate specifications to make sure they align with the requirements of your current system. If your sprayer demands a high flow rate for effective coverage, the pump should be capable of delivering that without straining or compromising the quality of the spray. Furthermore, consider any additional accessories you might want to incorporate, such as pressure regulators or filters, and ensure that the selected pump can accommodate these accessories without any modifications. By carefully evaluating compatibility, you can maximize the efficiency of your spraying tasks while minimizing the potential for complications down the line.

2025 How to Choose the Best 12 Volt Sprayer Pump for Your Needs - Evaluating Compatibility with Existing Equipment and Accessories

| Pump Model | Flow Rate (GPH) | Max Pressure (PSI) | Power Consumption (W) | Weight (lbs) | Suitable for Types of Spraying |

|---|---|---|---|---|---|

| Model A | 1.2 | 60 | 45 | 5.5 | General spraying |

| Model B | 2.0 | 70 | 50 | 6.0 | Fertilizer application |

| Model C | 1.5 | 50 | 35 | 4.8 | Pesticide spraying |

| Model D | 2.5 | 80 | 60 | 7.0 | Herbicide spraying |

| Model E | 1.0 | 40 | 30 | 4.0 | General cleaning |

Budgeting for Your 12 Volt Sprayer Pump Purchase and Maintenance Costs

When considering the purchase of a 12 Volt sprayer pump, budgeting is a crucial step that can significantly affect your overall investment. Reports indicate that the average cost of a quality 12 Volt sprayer pump ranges between $100 to $300, depending on the specifications and features. Additionally, maintenance costs are often overlooked, but they can add up over time. Regular maintenance, which may include occasional parts replacement, can average around $50 to $100 annually. This ongoing expense should be factored into your budget to ensure your pump operates efficiently and lasts longer.

Tips: Always assess your specific needs before making a purchase. Consider factors like the size of the area you’ll be spraying and the type of chemicals you will be using. Understanding these requirements can help you choose a model that not only fits your budget but also performs optimally for your tasks. Furthermore, researching industry insights, like average operational lifespan and expected maintenance frequency, can provide clarity and assist in budgeting appropriately for both initial purchase and ongoing costs.

Another important consideration is the energy consumption of your 12 Volt sprayer pump. Many models consume around 5 to 10 amps while in operation. Analyzing this data helps you estimate your power consumption costs. It is wise to calculate the total energy expenses over time to avoid any unexpected financial burdens from electricity bills. Making informed choices today can lead to significant savings in the future.

Related Posts

-

Ultimate Guide to Choosing the Best 12 Volt Sprayer Pump for Your Agricultural Needs

-

Top 10 Best 12 Volt Pumps for Every Need: Ultimate Buying Guide

-

Top Tips for Choosing the Best RV Water Pump for Your Needs

-

How to Choose the Best Electric Transfer Pump for Your Needs

-

How to Choose the Right Chemical Transfer Pump for Your Needs

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China