How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

In the industrial sector, the selection of a suitable chemical transfer pump is crucial for ensuring operational efficiency and safety. According to a report by Research and Markets, the global chemical pump market is projected to reach USD 7.58 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. This growth is indicative of the increasing demand for reliable and efficient pumps that can handle various aggressive substances safely. The right chemical transfer pump not only enhances fluid transfer processes but also mitigates environmental concerns associated with leaks or spills.

Moreover, as industries move toward more sustainable practices, selecting a pump designed for energy efficiency and reduced maintenance can lead to significant long-term cost savings. Given the diverse applications ranging from chemical manufacturing to oil and gas, understanding the specific requirements of your operations is essential for making the right choice in selecting a chemical transfer pump.

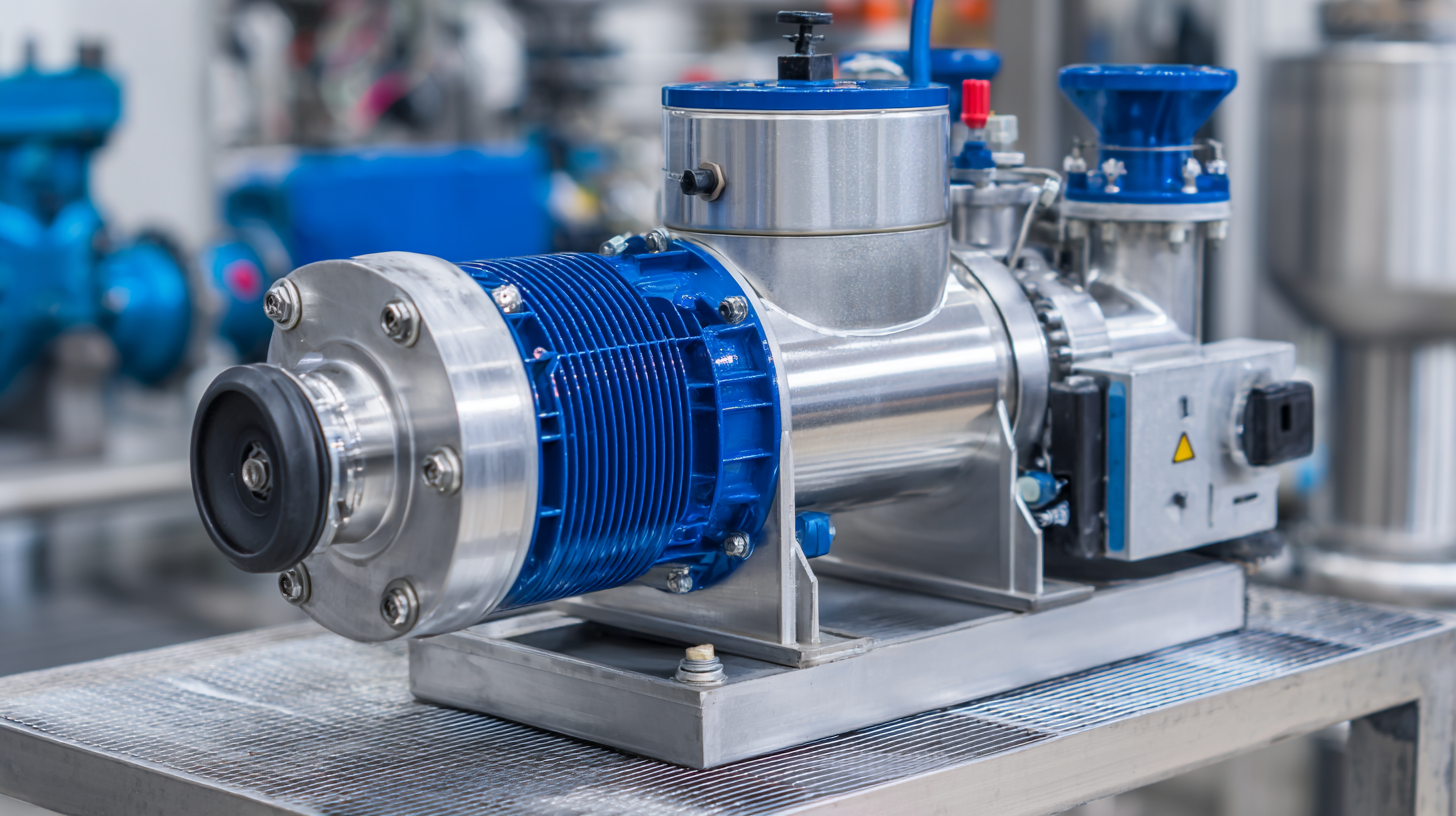

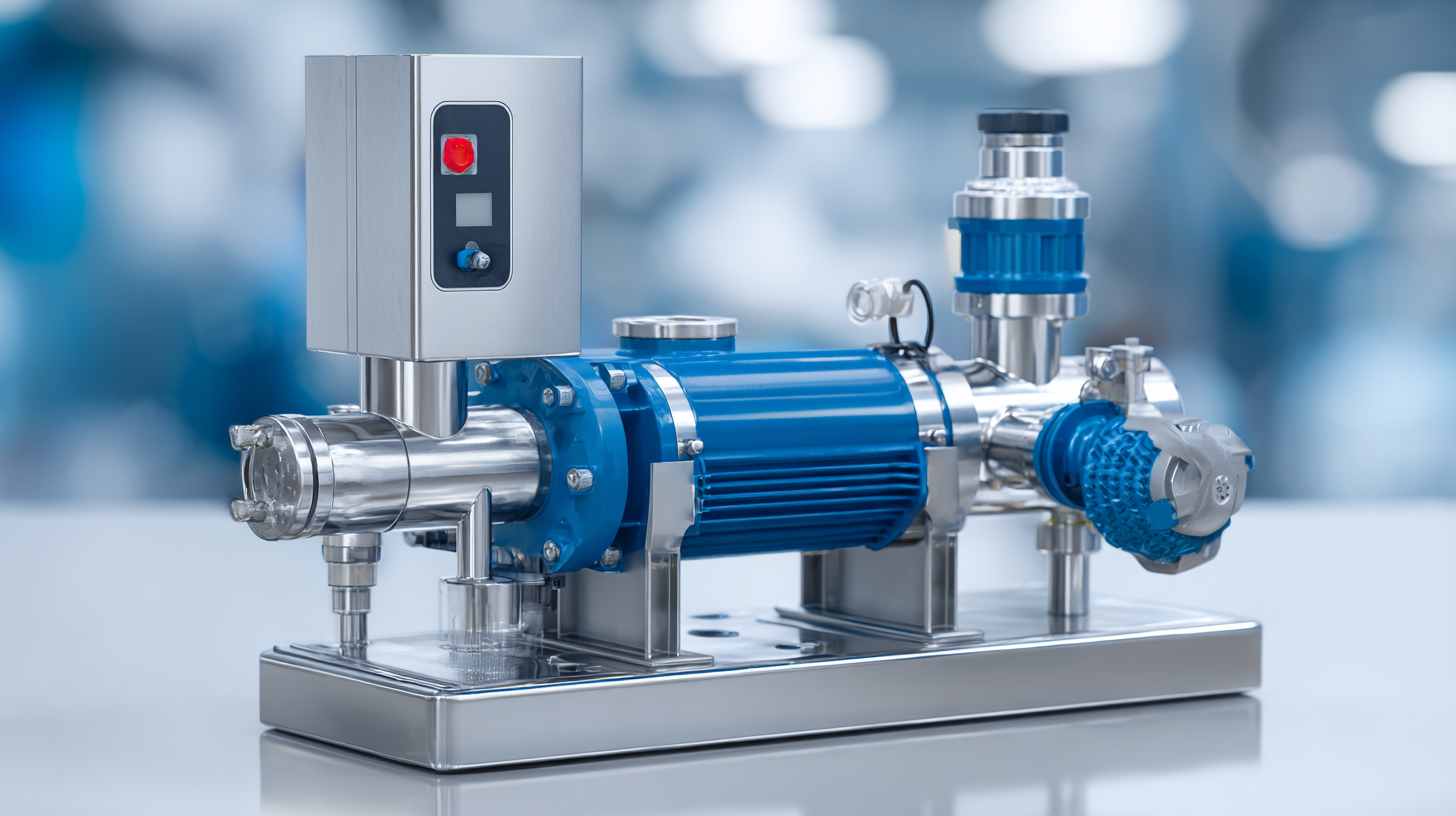

Understanding the Different Types of Chemical Transfer Pumps Available

When selecting the right chemical transfer pump for industrial applications, it is essential to understand the different types available. One common type is the positive displacement pump, known for its efficiency in handling viscous fluids and delivering uniform flow rates. These pumps operate by trapping a fixed amount of fluid and forcing it through the discharge, making them ideal for transferring chemicals in processes that require precision.

Another notable type is the magnetic drive chemical pump, which features a sealed system that enhances safety and prevents leaks. This design is particularly beneficial for corrosive or hazardous chemicals, as the absence of exposed seals reduces the risk of contamination. In addition, advancements in the industry have led to the development of standardized chemical pumps aimed at enhancing efficiency and reliability across various applications. Understanding these diverse pump technologies is crucial for selecting the right solution that meets specific industrial needs while ensuring safe and effective chemical transfer.

Identifying Your Specific Industrial Chemical Transfer Requirements

When selecting the appropriate chemical transfer pump for industrial applications, it's crucial to clearly identify the specific requirements dictated by the type of chemicals being handled. Understanding the unique properties of the chemicals involved—including their viscosity, corrosiveness, and potential hazards—is essential for determining the right pumping solution. For instance, when dealing with hazardous materials, safety features and compatibility with the chemicals should be prioritized to avoid leaks or reactions that could result in unsafe work conditions.

Moreover, the growing complexity of industrial processes, such as those seen in the advancements in biocatalysis and the adaptation to new materials, underscores the need for pumps that can efficiently manage varying chemical characteristics. Industries are increasingly utilizing specialized pumps that can handle fluctuating parameters seen in modern chemical synthesis and processing. Therefore, evaluating the transfer rates, energy efficiency, and reliability of different pump models is necessary to match the industrial needs with innovative solutions that support ongoing technological developments.

Evaluating Pump Performance Metrics for Optimal Efficiency

When selecting a chemical transfer pump for industrial applications, evaluating pump performance metrics is crucial for achieving optimal efficiency. Key metrics to consider include flow rate, pressure rating, and power consumption. The flow rate, usually measured in gallons per minute (GPM) or liters per minute (LPM), indicates how quickly a pump can transfer fluids. A pump that meets the required flow rate will ensure that operations run smoothly without unnecessary downtime.

Another vital performance metric is the pressure rating, which determines the pump's ability to overcome the system's resistance. High resistance in piping systems, particularly those with bends and turns, can significantly affect the pump's efficiency. Therefore, it’s essential to choose a pump with an adequate pressure rating that aligns with your system's design. Lastly, monitoring power consumption can reveal efficiency levels; pumps that consume less energy while maintaining performance help reduce operational costs. By focusing on these performance metrics, you can select a chemical transfer pump that not only meets your operational needs but also enhances overall efficiency.

Assessing Safety Features and Compliance Standards for Chemical Handling

When selecting a chemical transfer pump for industrial applications, assessing safety features and compliance standards is crucial. The pump must meet specific safety regulations set by organizations such as OSHA and EPA to ensure the protection of workers and the environment. Look for features like leak detection systems, double-walled tanks, and explosion-proof designs, which enhance safety by preventing hazardous spills and limiting exposure to toxic substances.

In addition to safety features, the pump's compliance with industry standards should be examined. Different chemicals may require pumps that adhere to specific guidelines, such as those outlined by the American National Standards Institute (ANSI) or the Hydraulic Institute. Ensuring that the pump is compatible with the chemicals being transferred and meets relevant industry certifications helps mitigate risks associated with chemical handling. By prioritizing safety and compliance, industries can protect employees and ensure efficient operations while handling potentially dangerous substances.

Comparing Costs and Maintenance Needs of Various Pump Options

When selecting a chemical transfer pump for industrial applications, understanding the costs and maintenance requirements of various options can significantly impact your decision. Different types of pumps, such as diaphragm, gear, and centrifugal pumps, vary not only in their initial purchase price but also in long-term operational costs.

Diaphragm pumps, for instance, may have higher upfront costs due to their complex design but often require less maintenance, making them a cost-effective option over time for certain chemical transfers.

Diaphragm pumps, for instance, may have higher upfront costs due to their complex design but often require less maintenance, making them a cost-effective option over time for certain chemical transfers.

Maintenance considerations are equally critical, as they directly affect operational efficiency and downtime. Some pumps require regular lubrications and seal replacements, which add to the overall maintenance cost. Centrifugal pumps, while typically less expensive initially, may demand frequent servicing if not used within their optimal conditions, leading to higher long-term costs. Additionally, understanding the chemical compatibility and environmental conditions can guide you towards a pump that minimizes wear and tear, thus effectively reducing maintenance needs and extending the pump’s lifespan. By carefully comparing these factors, you can make an informed choice that aligns with your industrial requirements.

Related Posts

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry

-

Challenges Encountered with Submersible Pumps in Industrial Applications

-

How to Choose the Right Electric Sprayer Pump for Your Needs

-

5 Smart Tips to Choose the Best Small Electric Water Pump