How to Choose the Best Electric Transfer Pump for Your Needs

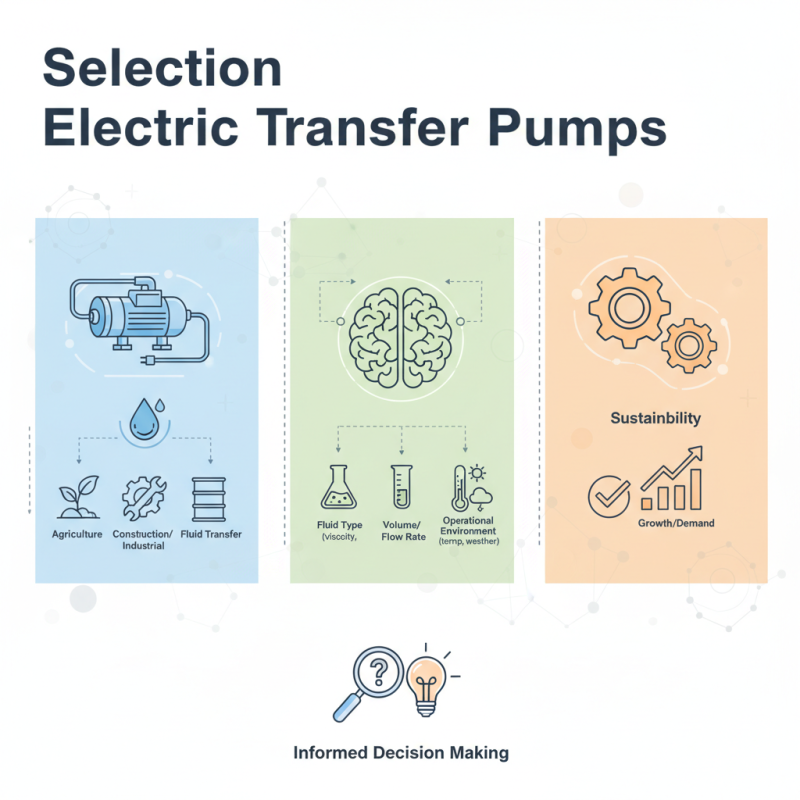

In the ever-evolving landscape of fluid transfer solutions, the electric transfer pump has emerged as a vital tool across various industries, from agriculture to construction. According to a recent Market Research Report by Transparency Market Research, the global electric transfer pump market is projected to grow at a CAGR of 5.2% over the next five years, indicating a robust demand driven by efficiency and sustainability concerns. Professionals looking to choose the best electric transfer pump for their unique needs must navigate a myriad of options, each designed to cater to specific fluid types, volumes, and operational environments.

Industry expert Dr. Emily Sanchez, a leading engineer in fluid dynamics, emphasizes the importance of matching the pump's capabilities to the intended application: "Selecting the right electric transfer pump is not just about power and size; it’s about understanding the specific requirements of the fluid being transferred, as well as the conditions of the environment it will operate in." This insight underscores the crucial aspect of informed decision-making that can significantly impact operational efficiency and cost-effectiveness. As users delve deeper into their options, comprehending the functionalities and specifications of electric transfer pumps will empower them to make choices that align closely with their operational goals.

Understanding Electric Transfer Pumps and Their Applications

Electric transfer pumps are versatile tools designed to move liquids efficiently from one location to another. They are commonly used in various applications, including draining water from basements, transferring fuel, or even managing agricultural irrigation systems. Understanding the specific needs of your application is essential when selecting the right pump, as different models come with distinct features, capacities, and operational mechanisms.

Tips for choosing the best electric transfer pump include assessing the viscosity of the liquid you intend to transfer. Thicker liquids may require pumps specifically designed to handle such fluid characteristics. Additionally, consider the power source and portability; some applications may benefit from battery-operated models for convenient use in remote locations. Lastly, check the pump's flow rate to ensure it meets your volume transfer needs within the required time frame.

When selecting an electric transfer pump, it's also crucial to evaluate safety features. Look for pumps that provide thermal overload protection and have durable materials that can withstand the chemical properties of the liquids being transferred. These considerations not only extend the lifespan of the pump but also enhance operational safety, ensuring that your tasks are carried out with minimal risk.

Electric Transfer Pump Flow Rates Comparison

Key Features to Look for in Electric Transfer Pumps

When selecting an electric transfer pump, it’s essential to consider several key features to ensure it meets your specific needs. One of the primary factors to evaluate is the pump's flow rate, which is typically measured in gallons per minute (GPM). According to industry reports, transfer pumps usually offer flow rates ranging from 3 to 30 GPM. For instance, if you're transferring large volumes of water or fuel, a higher flow rate will save you substantial time and effort.

Another crucial feature is the pump's power source and motor capacity. Most electric transfer pumps operate using standard household outlets, making them convenient for residential use. However, higher-capacity pumps may require dedicated circuits. An industry analysis indicates that pumps with a motor power of at least 1/2 horsepower can efficiently handle most tasks. Additionally, consider the material of the pump’s housing and impeller, as corrosion-resistant materials such as stainless steel or heavy-duty plastic significantly enhance durability and lifespan, especially in harsh environments.

Lastly, the portability and ease of use of the pump should not be overlooked. Many models come equipped with features like lightweight designs, built-in handles, or wheeled frames. Investing in a pump that emphasizes user-friendly operation and mobility can greatly enhance efficiency, particularly in situations requiring frequent repositioning. As reports show, users consistently note that convenience features significantly impact overall user satisfaction and productivity in diverse applications.

Assessing Pump Capacity and Flow Rate for Your Needs

When selecting the best electric transfer pump for your needs, one of the most critical factors to consider is pump capacity. This refers to the maximum volume of liquid the pump can handle within a specific time frame, usually measured in gallons per minute (GPM) or liters per hour (LPH). Understanding your application will help you determine the required capacity. For instance, if you need to transfer large volumes of water for irrigation, a pump with a higher capacity would be essential. Conversely, if your purpose is to transfer smaller amounts of liquid, a lower capacity pump may suffice. Always ensure that the pump capacity aligns with your intended use to maximize efficiency and avoid any unnecessary strain on the equipment.

Flow rate is another vital element when assessing the right electric transfer pump. It represents how quickly the pump can move fluid from one point to another. For tasks that demand rapid transfer, such as draining a swimming pool or quickly removing water from a flooded area, a pump with a higher flow rate is preferable. However, if your project allows for slower transfer speeds, a pump with a moderate flow rate can be more energy-efficient and cost-effective. It’s important to balance your needs by evaluating both the total fluid volume and the time frame in which it needs to be transferred, ensuring you select a pump that best fits your operational requirements.

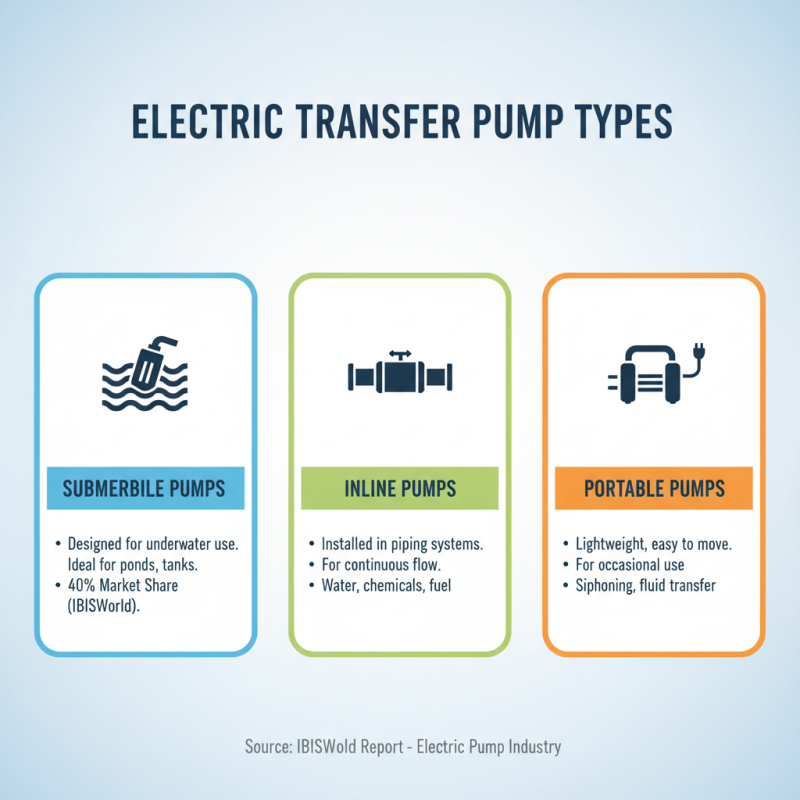

Comparing Different Types of Electric Transfer Pumps

When selecting the best electric transfer pump, understanding the different types available is crucial to making an informed decision. Electric transfer pumps primarily fall into three categories: submersible, inline, and portable pumps. Submersible pumps are designed to be submerged in the liquid they are transferring, making them ideal for ponds or tanks where the pump can be easily accessed underwater. According to a report by IBISWorld, submersible pumps account for approximately 40% of the market share in the electric pump industry due to their efficiency and versatility in various applications.

Inline pumps, on the other hand, are typically used for applications where the liquid needs to be moved from one reservoir to another without immersing the pump in the fluid. These pumps offer high flow rates and pressure capabilities, making them suitable for industrial settings and larger projects. A recent market analysis highlighted that inline electric transfer pumps saw a 15% increase in demand over the past year, driven by growth in the construction and manufacturing sectors. Lastly, portable electric transfer pumps, known for their mobility, are perfect for small-scale tasks or for use in locations where permanent installation is impractical. These versatile pumps have gained popularity, with a significant rise in sales noted in DIY and home improvement markets.

Each type of electric transfer pump presents unique advantages that cater to specific needs, emphasizing the importance of assessing factors such as application, flow rate requirements, and portability before making a purchase decision. Understanding these distinctions not only streamlines the selection process but also ensures that users choose a pump that aligns perfectly with their operational demands.

Maintenance and Care Tips for Electric Transfer Pumps

Proper maintenance and care are crucial for ensuring the longevity and efficiency of your electric transfer pump. Regularly inspect the pump for any signs of wear or damage, such as leaks or unusual noises during operation. Keeping the pump clean is vital; it’s essential to remove any dirt or debris that may accumulate on or around the pump. Use a damp cloth or a soft brush to clean the exterior, and be cautious to avoid damaging any electrical components.

Additionally, it is important to check the fluid levels and the quality of the liquids being transferred. Using the pump within its recommended specifications prevents unnecessary strain on the motor and prolongs its lifespan. After each use, empty the pump and flush it with a suitable cleaning solution to prevent any residue build-up. Furthermore, storing the pump in a dry and cool place when not in use can protect it from environmental damage, ensuring that it remains in top working condition for your future needs.

Related Posts

-

10 Essential Tips for Choosing the Best Electric Transfer Pump for Your Needs

-

Revolutionizing Fluid Handling: The Essential Guide to Electric Transfer Pumps for Every Need

-

What is a High Pressure Pump and How Does it Work Efficiently

-

Exploring the Best Small Pumps for Home and Garden: Your Ultimate Buying Guide

-

Discovering the Advantages of Electric Diaphragm Pumps: Efficiency, Versatility, and Applications

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance