How to Choose the Right Industrial Pumps for Your Business Needs

Choosing the right industrial pumps for your business can significantly impact operational efficiency. The industrial pumps market is projected to reach $100 billion by 2025, according to a recent report from Market Research Future. Understanding your specific requirements is critical.

Experts like John Carter, a widely recognized authority in the industrial pumps sector, emphasize, “Selecting the right pump can save companies time and money.” Each industry presents unique challenges. What works in one may not suit another. For instance, pumps used in chemical processing must handle corrosive substances, while those in water treatment need durability in harsh environments.

Yet, many businesses overlook critical factors. They often focus solely on price or brand reputation. This can lead to mismatches, increased maintenance costs, and operational downtime. Reflecting on these aspects can pave the way for better choices in industrial pumps. Take the time to assess what your business truly needs to thrive.

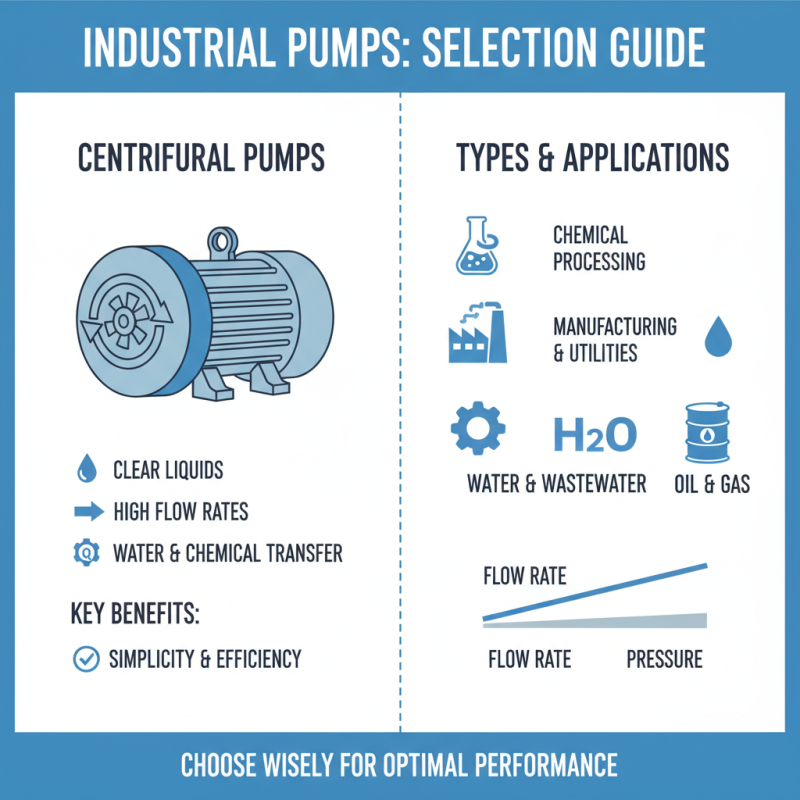

Understanding Different Types of Industrial Pumps and Their Applications

Choosing the right industrial pumps requires understanding their various types and applications. There are centrifugal pumps, commonly used for clear liquids. They efficiently transfer water and chemicals when high flow rates are needed. The simplicity of these pumps makes them a popular choice.

Then, there are positive displacement pumps. They work by trapping a fixed amount of fluid and forcing it through the outlet. These are ideal for viscous liquids, such as oils and slurries. However, they require careful control to avoid over-pressurization. Improper selection can lead to equipment failure or damage.

Another type is submersible pumps. These are submerged in the fluid being pumped, making them useful for drainage and sewage applications. However, they come with a risk of corrosion, so material choice is critical. It’s essential to evaluate the specific needs of your application. Understanding these details leads to better decision-making and long-term efficiency.

Key Factors to Consider When Selecting Industrial Pumps for Your Business

Choosing the right industrial pump can feel overwhelming. Key factors should guide your selection. First, consider the fluid type you'll be pumping. Different fluids require different pump designs. For example, abrasive materials need robust pumps to avoid wear and tear.

Another important factor is the required flow rate. Depending on your operations, you might need pumps that handle high volumes. Industry reports suggest that over 80% of facilities will have flow rate needs exceeding 100 GPM. This underlines the necessity of calculating your requirements accurately.

Tip: Always account for peak demand when assessing flow rates.

Power requirements are another crucial aspect. Assess the energy efficiency of the pump. Efficient pumps can save up to 25% on energy costs annually. Yet, many businesses overlook this. Depending on your local energy rates, this can lead to significant savings.

Tip: Consider the lifecycle costs. Cheaper pumps may cost you more in the long run.

Finally, don’t forget maintenance considerations. Some pumps require more upkeep than others. A lack of proper maintenance can lead to failures that cost time and money. Always take the time to compare maintenance demands before making a choice.

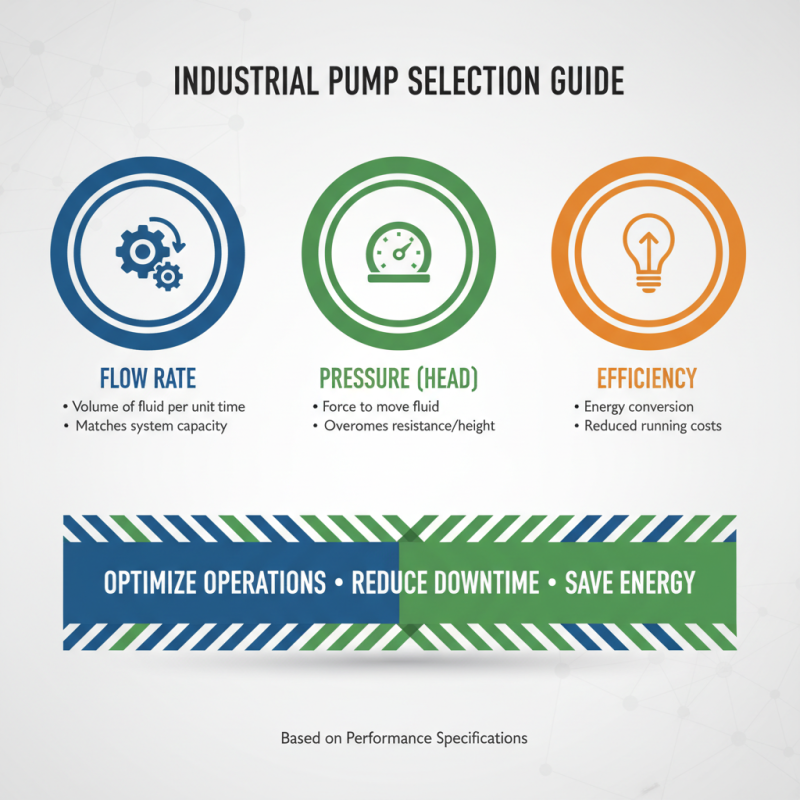

Evaluating Performance Specifications for Optimal Pump Efficiency

Choosing the right industrial pumps requires careful evaluation of performance specifications. Pay attention to flow rate, pressure, and efficiency. These factors directly affect your operations. An efficient pump reduces energy costs and minimizes downtime.

Tips: Always analyze your system requirements first. Understand the fluid being pumped. This knowledge helps in selecting materials and pump types. Don't overlook maintenance requirements. A pump that is hard to service may cause delays.

Consider the environment where the pump operates. Temperature fluctuations and corrosive substances can affect performance. A mismatch can lead to frequent repairs. Reassess your choices as your business grows. What works now may not serve you later. Always keep an eye on evolving technologies that may enhance efficiency.

Assessing Maintenance Requirements and Life Cycle Costs of Pumps

When selecting industrial pumps, understanding maintenance requirements is crucial. A pump that needs frequent repairs can drain resources quickly. Each model comes with different maintenance needs. Some require regular inspections, while others may need parts replaced more often. Consider these factors carefully.

Life cycle costs cannot be ignored. The sticker price isn't everything. Operating costs, energy consumption, and maintenance fees add up over time. A pump with a low initial cost might end up being expensive. Assessing these expenses helps in making a better decision. You might also need to think about potential downtimes during repairs.

It's important to learn from past experiences. Sometimes, businesses overlook the long-term impacts of their choices. A hasty decision can lead to poor performance later on. Analyze both current and future needs. This process can reveal which pumps truly fit your operational demands. Don't rush; reflection can save you money and time.

Making Informed Choices: Supplier Reputation and Support Services

Choosing the right industrial pumps can be daunting. One major factor is the supplier's reputation. A well-regarded supplier often indicates reliable products. Check online reviews and testimonials. Look for feedback on their customer support and service quality.

Tips: Reach out to other businesses in your industry for recommendations. A personal experience can reveal a lot about a supplier.

Support services are crucial after the purchase. Does the supplier provide maintenance? Are they available for troubleshooting? Quick response times matter, especially in emergencies. If the supplier’s support is lacking, it can lead to downtime and losses.

Tips: Evaluate the supplier’s service agreements. Understand what’s included and any additional costs involved. Don’t overlook this aspect; it can have long-lasting impacts.

Choosing the Right Industrial Pumps Based on Supplier Reputation and Support Services

Related Posts

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China

-

Revolutionizing Fluid Handling: The Essential Guide to Electric Transfer Pumps for Every Need

-

Exploring the Impact of 24v Water Pump Innovations at the 138th China Import and Export Fair 2025

-

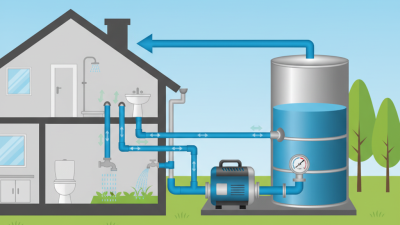

What is a Water Tank Pump and How Does It Work for Your Home

-

5 Smart Tips to Choose the Best Small Electric Water Pump