How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

In today's water-scarce environment, the selection of a

pressure pump for water efficiency has become increasingly critical. According to a report by the

U.S. Environmental Protection Agency, over

72 billion gallons of water are wasted daily due to inefficient

water delivery systems, highlighting the need for industry-standard solutions. Choosing the right

pressure pump for water not only ensures optimal performance but also significantly

contributes to conservation efforts. The International Organization for Standardization (ISO)

estimates that implementing high-efficiency pumps can reduce energy consumption by up to 30%,

translating into substantial cost savings and a lower environmental impact. As industries strive to meet

both regulatory requirements and sustainability goals, understanding how to select

a pressure pump that aligns with water efficiency standards is essential for fostering responsible water

management practices.

In today's water-scarce environment, the selection of a

pressure pump for water efficiency has become increasingly critical. According to a report by the

U.S. Environmental Protection Agency, over

72 billion gallons of water are wasted daily due to inefficient

water delivery systems, highlighting the need for industry-standard solutions. Choosing the right

pressure pump for water not only ensures optimal performance but also significantly

contributes to conservation efforts. The International Organization for Standardization (ISO)

estimates that implementing high-efficiency pumps can reduce energy consumption by up to 30%,

translating into substantial cost savings and a lower environmental impact. As industries strive to meet

both regulatory requirements and sustainability goals, understanding how to select

a pressure pump that aligns with water efficiency standards is essential for fostering responsible water

management practices.

Understanding the Importance of Pressure Pumps in Water Efficiency

Pressure pumps play a crucial role in enhancing water efficiency across various industries, making them indispensable for sustainable water management. According to the U.S. Environmental Protection Agency (EPA), inefficient water systems can lead to a loss of up to 30% of water in distribution, primarily due to pressure imbalances. By selecting the right pressure pump, organizations can optimize their water delivery systems, thereby minimizing waste and ensuring that water reaches its intended destinations effectively.

Furthermore, the International Journal of Water Resources Development highlights that properly chosen pressure pumps can improve energy efficiency by up to 40%. This is particularly important in agricultural settings where the demand for irrigation is high. Selecting pumps that comply with industry standards, such as those specified by the American Society of Mechanical Engineers (ASME), ensures that they operate within optimal pressure ranges, greatly reducing the risk of leaks and over-expenditure on energy. With these standards in mind, industries can not only achieve significant cost savings but also contribute to broader environmental sustainability goals.

Key Industry Standards for Selecting Pressure Pumps for Water Systems

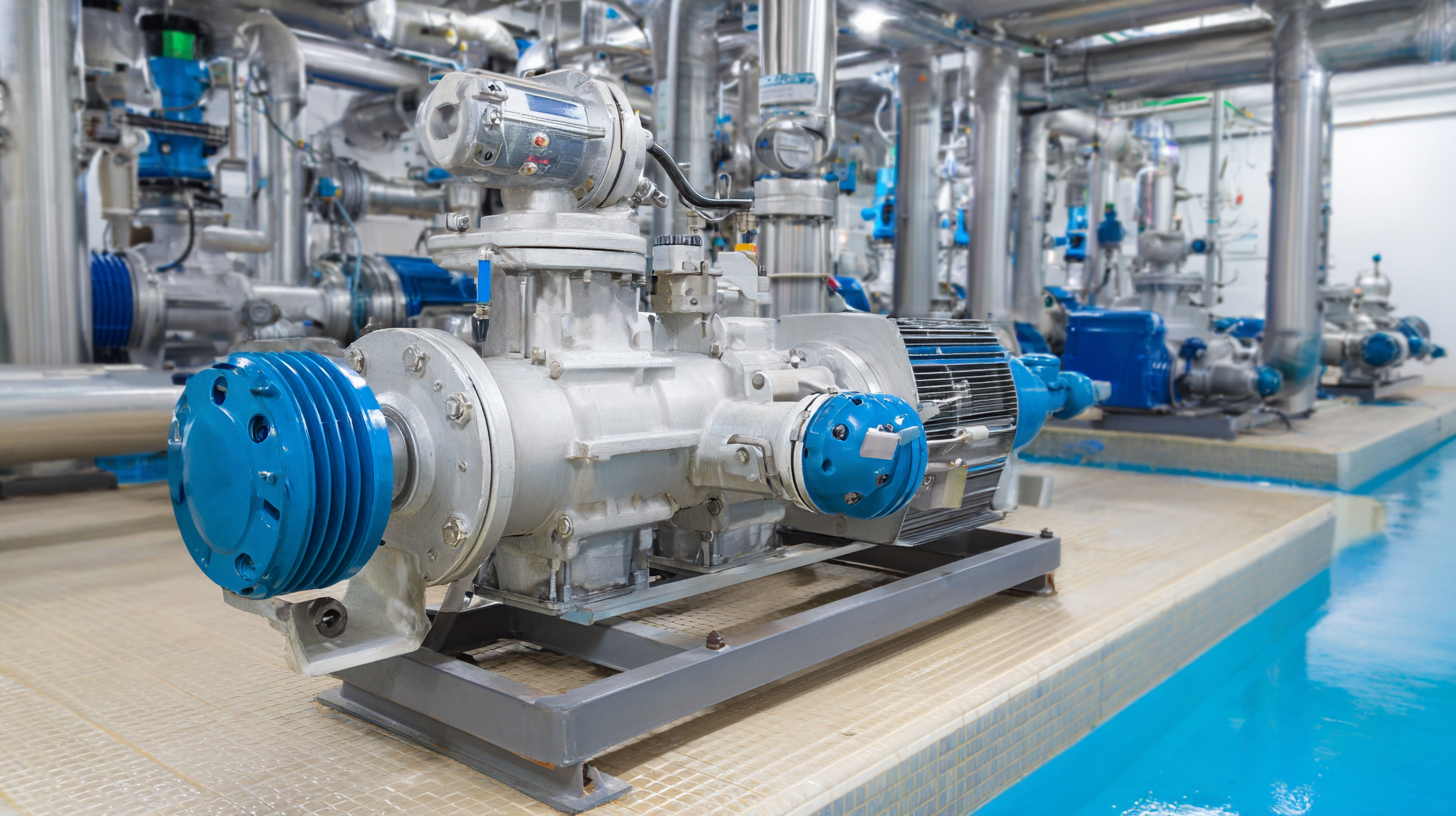

When selecting a pressure pump for water systems, understanding key industry standards is crucial for ensuring water efficiency and optimal system performance. One of the primary standards to consider is the Energy Efficiency Index (EEI), which evaluates the pump's energy consumption relative to its performance. Pumps that meet or exceed these efficiency standards not only reduce operational costs but also minimize environmental impact, aligning with sustainable practices.

Another important standard is the Hydraulic Institute Standards (HIS), which provide guidelines on pump design, testing, and application. These standards help in assessing the hydraulic performance of pumps, ensuring they can handle varying flow conditions and pressures effectively. Additionally, compliance with International Organization for Standardization (ISO) standards can further assure that the pump is manufactured and tested according to globally recognized benchmarks, thereby enhancing reliability and longevity.

By focusing on these industry standards, you can make informed decisions when selecting a pressure pump that not only meets your specific water efficiency needs but also contributes to the overall sustainability of your operations.

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

| Parameter | Description | Recommended Standard | Efficiency Rating |

|---|---|---|---|

| Flow Rate | Measurement of the volume of water that the pump can move. | ISO 9906 | ≥ 85% |

| Power Consumption | Power required for the pump to operate efficiently. | IEC 60034 | ≤ 0.5 kW/m³/h |

| Total Dynamic Head | Height the pump can lift water against gravitational forces. | Hydraulic Institute Standards | Min 20m |

| Material Efficiency | Durability and corrosion resistance of pump materials. | ASME B73.1 | Grade A or better |

| Noise Level | Sound generated by the pump during operation. | ISO 3744 | ≤ 60 dB |

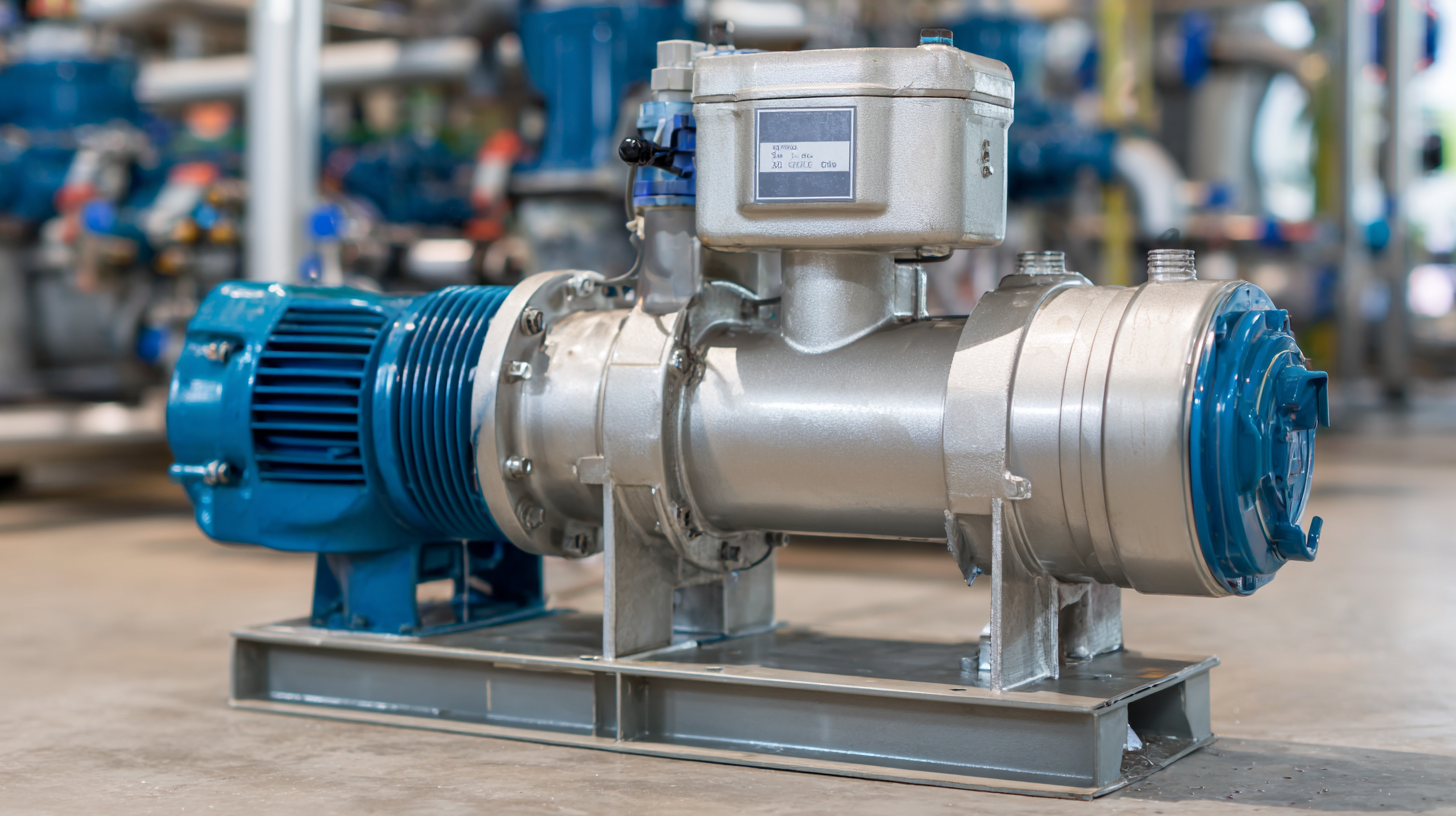

Factors to Consider When Choosing the Right Pressure Pump for Your Needs

When selecting the right pressure pump for your water efficiency needs, several key factors come into play. Firstly, understanding the pump's flow rate is crucial. The American Society of Mechanical Engineers (ASME) suggests that for optimal efficiency, flow rates should match the specific demands of your application. For instance, residential water systems typically need a flow rate between 8 to 15 gallons per minute (GPM), while larger industrial systems may require significantly higher rates.

Another important consideration is the pump's energy efficiency rating. According to the Hydraulic Institute, choosing a pump with an efficiency rating of 85% or higher can lead to substantial energy savings over time. This not only reduces operational costs but also contributes to a more sustainable environment.

**Tips:** Always consult efficiency performance curves provided by manufacturers, as they help in understanding how the pump will operate under various conditions. Additionally, consider selecting a pump with variable frequency drives (VFDs) for enhanced control over flow rates, which can improve overall water efficiency in your systems. By focusing on these critical factors, you can ensure that you select a pressure pump that meets your needs while adhering to industry standards.

Water Efficiency in Pressure Pumps

Comparing Different Types of Pressure Pumps for Optimal Water Efficiency

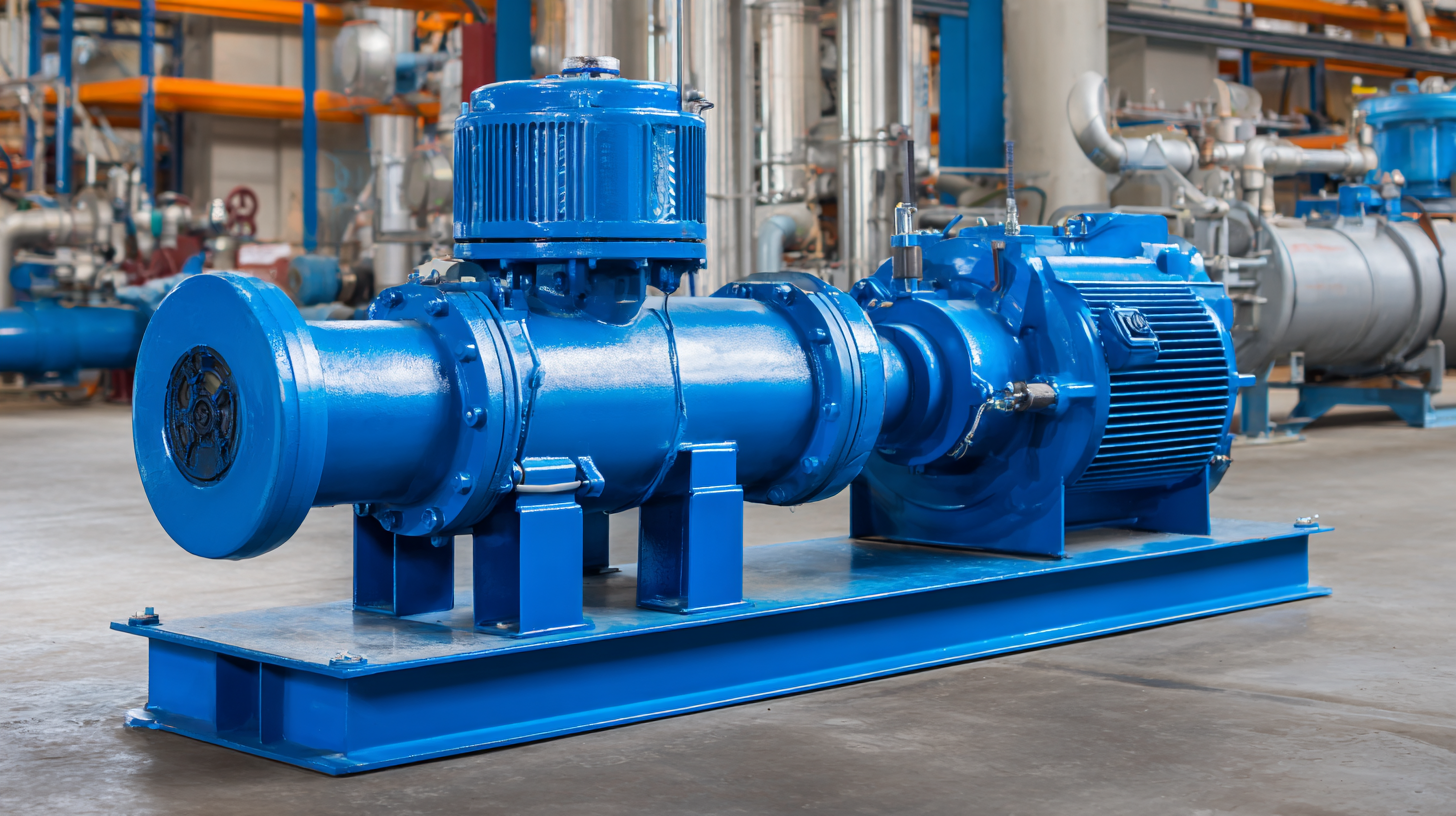

When choosing a pressure pump for optimal water efficiency, understanding the various types available can significantly impact performance. The three common types of pressure pumps are Centrifugal, Positive Displacement, and Submersible pumps, each serving distinct purposes and efficiencies. According to the U.S. Department of Energy, centrifugal pumps are widely used in agricultural and municipal applications, translating to energy savings of up to 20% when properly sized for the application. Their design allows for efficient water flow, making them ideal for systems that require consistent pressure over variable flow rates.

Positive displacement pumps, on the other hand, are perfect for applications demanding high pressure and low flow rates. A 2022 report by the Water Research Foundation revealed that these pumps could achieve efficiencies upwards of 85%, particularly in scenarios involving thick liquids or slurries. Meanwhile, submersible pumps are ideal for deep well applications; the Hydraulic Institute notes that these pumps provide increased reliability and reduced maintenance costs due to their submerged operation.

Ultimately, the choice of pump should align with the specific requirements of the application while adhering to industry standards. Regular assessments and adherence to guidelines set out by organizations like the American Society of Mechanical Engineers (ASME) can help ensure that the selected pump not only meets the operational needs but also promotes water efficiency.

Evaluating Pump Performance: Metrics to Assess Water Efficiency Standards

When selecting a pressure pump that meets water efficiency standards, evaluating its performance metrics is crucial. Key indicators such as flow rate, power consumption, and overall efficiency can directly impact both operational costs and environmental sustainability. Understanding these metrics allows for informed decisions that align with industry standards, ensuring optimal water usage across various applications.

Tips: When assessing flow rate, consider the specific requirements of your application to avoid under or over-sizing the pump. Additionally, analyze the power consumption in relation to the pump's efficiency rating; a higher initial investment in an efficient model may yield substantial savings over time.

It's also essential to examine the pump's lifespan and maintenance requirements. A pump designed for durability will not only save costs in the long run but also reduce downtime. Make sure to check for certifications that indicate compliance with recognized water efficiency standards, which can further guarantee performance reliability and efficiency in real-world conditions.

Related Posts

-

Ultimate Guide to Choosing the Right Water Pump for Your Needs

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

Ultimate Guide to Choosing the Best 12 Volt Sprayer Pump for Your Agricultural Needs

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry