How to Choose the Right Chemical Transfer Pump for Your Needs

In today's industrial landscape, the significance of selecting the appropriate chemical transfer pump cannot be overstated. As industries increasingly rely on efficient fluid management systems, the global chemical pump market is projected to reach USD 15.7 billion by 2025, growing at a compounded annual growth rate (CAGR) of approximately 5.3% during the forecast period. This growth is driven by the rising demand for chemical processing in various sectors, including pharmaceuticals, food and beverage, and oil and gas. The right chemical transfer pump not only ensures the safe and efficient movement of liquids but also minimizes operational risks and enhances overall productivity.

Choosing the right chemical transfer pump is a critical decision that can have far-reaching implications for operational efficiency and safety. Factors such as viscosity, temperature, and chemical compatibility must be taken into consideration, alongside the specific application requirements. According to industry standards, improper selection can lead to increased downtime, maintenance costs, and even hazardous situations, underscoring the importance of thorough research and understanding of technical specifications. As organizations strive to optimize their processes, making an informed choice regarding chemical transfer pumps becomes essential to achieving both operational excellence and regulatory compliance.

Factors to Consider When Selecting a Chemical Transfer Pump

When selecting the right chemical transfer pump, it’s essential to consider several key factors that will impact both efficiency and safety in your operations. First, assess the type of chemicals you will be transferring. Some pumps are better suited for corrosive or abrasive substances, while others are designed for high-viscosity fluids. Understanding the chemical properties, including their pH, temperature, and potential for solid particles, will help narrow down your options significantly.

Another crucial aspect is the pump's materials of construction. The materials need to be compatible with the chemicals to prevent leaks, corrosion, or degradation of the pump over time. Common materials include stainless steel, PVC, and polypropylene; each has its benefits depending on the application. Additionally, consider the pump's flow rate and pressure requirements. These specifications directly affect how quickly and effectively you can transfer your chemicals, so ensure the pump can handle your operational needs.

**Tips:** When in doubt, consult with manufacturers or industry experts to determine the best pump for your application. Also, always review safety features like anti-drip mechanisms and explosion-proof designs to ensure safe handling during transfers. Lastly, consider the ease of maintenance and availability of replacement parts to prolong the life of your pump.

How to Choose the Right Chemical Transfer Pump for Your Needs

| Factor | Description | Importance | Example |

|---|---|---|---|

| Chemical Compatibility | Ensure the pump materials can handle the chemicals being transferred. | High | Acid-resistant pumps for acidic substances |

| Flow Rate | The volume of fluid the pump can move per unit time. | Medium | Pumps rated for 5-100 GPM |

| Pressure Requirements | Maximum pressure of the system where the pump will operate. | High | Pumps for high-pressure systems |

| Pump Type | Different types include centrifugal, diaphragm, and peristaltic pumps. | Medium | Centrifugal pump for water, diaphragm pump for viscous fluids |

| Portability | Consider if the pump needs to be moved frequently. | Low | Portable pumps for field use |

| Power Source | Electric, pneumatic, or manual operation options. | Medium | Electric pumps for indoor use |

| Maintenance | Consider the ease of maintenance and availability of spare parts. | High | Pump with accessible parts for easy servicing |

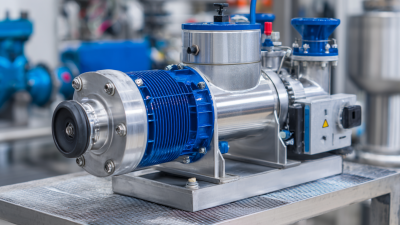

Types of Chemical Transfer Pumps and Their Applications

When selecting a chemical transfer pump, it's crucial to understand the various types available, as each is designed for specific applications. Positive displacement pumps are often used for transferring viscous fluids, providing a consistent flow rate regardless of pressure changes. They are ideal for applications involving thick chemicals or when precise dosing is required. On the other hand, centrifugal pumps are suitable for low-viscosity liquids and are favored for their efficiency and high flow rates. They work best in applications where the chemical's characteristics allow for smooth pumping without the need for high-pressure outputs.

Another important category is diaphragm pumps, which are known for their ability to handle corrosive and abrasive chemicals. These pumps utilize a flexible diaphragm to create a sealing action, preventing leaks and allowing for safer handling of hazardous materials. Magnetic drive pumps also play a significant role, particularly in situations where leakage could pose serious risks. By eliminating traditional seals, these pumps offer a leak-free operation, making them suitable for critical processes in various industries.

Ultimately, the choice of a chemical transfer pump should align with the specific requirements of the application, including the type of fluid, flow rate, and safety considerations. Understanding these types can significantly enhance operational efficiency and promote safe handling of chemicals.

Assessing Flow Rate and Pressure Requirements

When selecting a chemical transfer pump, one of the primary considerations is the flow rate required for your specific application.

Flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), is crucial as it determines how quickly you can transfer chemicals.

Industry standards suggest that for optimal performance, the flow rate should match the operational demands of your system.

For instance, according to the Hydraulic Institute, the average flow rate for chemical transfer pumps ranges from 5 GPM to over 100 GPM, depending on the application and chemical being transferred.

Understanding your system’s flow requirements will help you avoid underperformance or overloading the pump.

In addition to flow rate, assessing pressure requirements is equally vital.

Pressure, measured in pounds per square inch (PSI), affects how effectively a pump can move chemicals through the system, especially in applications requiring the fluid to reach significant heights or distances.

The American Society of Mechanical Engineers (ASME) notes that higher pressure may be required for viscous fluids or when operating against substantial friction in the piping system.

Therefore, when evaluating pump specifications, you should ensure the model chosen can handle the maximum pressure needs of your system without risking damage to either the pump or the transferred fluid.

Proper assessment of both flow rate and pressure will ensure efficient and safe chemical handling in your operations.

Material Compatibility and Construction of Pumps

When selecting a chemical transfer pump, material compatibility and construction are crucial factors that directly influence the pump's performance and longevity. According to a 2022 report from the Chemical Engineering Society, over 30% of pump failures in industrial applications are attributed to improper material selection. This statistic emphasizes the need for thorough consideration of the chemicals being transferred, as materials can vary significantly in their resistance to corrosion, abrasion, and temperature fluctuations. Common materials used in pump construction include stainless steel, polyethylene, and fluoropolymers, each offering specific advantages based on the chemical properties of the substances involved.

Different environments require tailored solutions, making it essential to evaluate the pump's construction concerning chemical compatibility. A study conducted by the Fluid Handling Institute indicated that pumps made with thermoplastic materials exhibit superior resistance to aggressive chemicals, thus extending service life compared to traditional metallic pumps. Additionally, factors such as pressure ratings, temperature limits, and the potential for chemical crystallization should be taken into account when determining the appropriate pump material. Investing time in selecting the right materials not only contributes to operational efficiency but also minimizes maintenance costs, ultimately enhancing the overall safety and reliability of chemical transfer processes.

Chemical Transfer Pump Material Compatibility

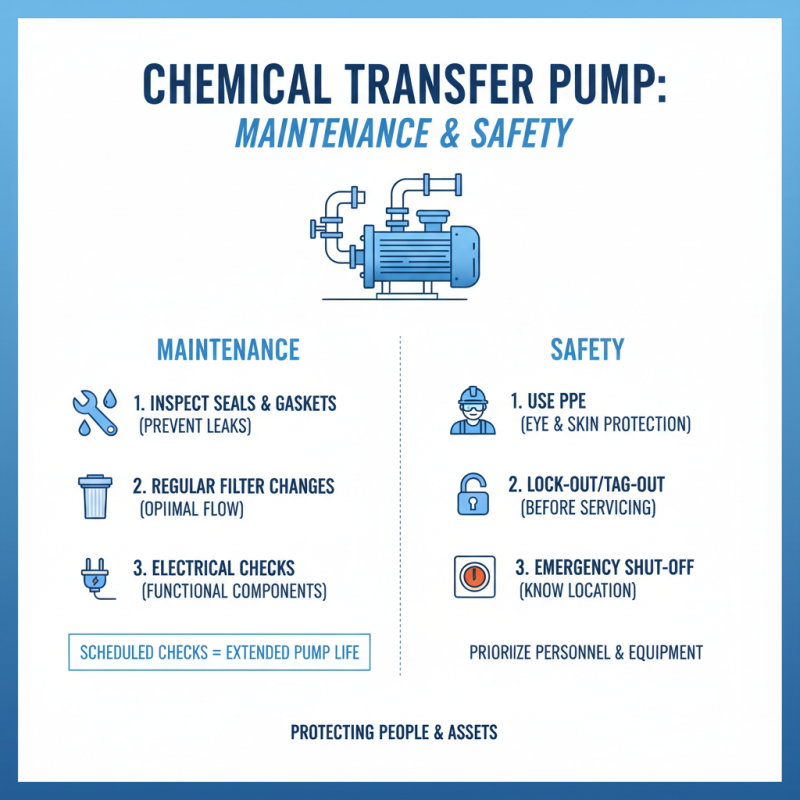

Maintenance and Safety Considerations for Pump Use

When operating a chemical transfer pump, ensuring proper maintenance and adhering to safety considerations are paramount to protect both the equipment and personnel involved. Regular maintenance checks help extend the lifespan of the pump and ensure that it functions efficiently. Key maintenance tasks include inspecting seals and gaskets for leaks, regularly changing filters, and ensuring that all electrical components are functioning correctly. A maintenance schedule tailored to the specific pump model and usage frequency can greatly reduce the risk of unexpected failures.

Tips: Always keep a detailed log of maintenance activities to track any changes or repeated issues. This record can be invaluable in diagnosing problems early and developing an effective maintenance routine.

Safety is another critical aspect of pump operation. Users should always read the manual thoroughly to understand the equipment and its limitations. Personal protective equipment (PPE) such as gloves, goggles, and aprons should be worn to prevent exposure to hazardous chemicals. Additionally, ensuring proper ventilation in the area where the pump operates helps mitigate the risk of harmful fumes and improves overall working conditions.

Tips: Designate a clear area for pump operation, free from obstructions. This minimizes the risk of accidents and allows for a swift response in case of an emergency. Regularly training staff on safety protocols also helps maintain a culture of safety awareness.

Related Posts

-

Exploring Innovative Chemical Pump Alternatives for Industrial Applications

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

Exploring Innovative Alternatives to Chemical Pumps for Enhanced Efficiency and Reliability

-

2025 Ultimate Guide: How to Choose the Right Bleach Pump for Your Needs

-

Exploring the Efficiency of Electric Transfer Pumps: A Detailed Study on Flow Rates and Energy Consumption Trends

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success