How to Choose the Right Diaphragm Pump for Your Needs?

Choosing the right diaphragm pump can significantly affect your operations. With various options available, it can be overwhelming. A key consideration is the type of fluid you'll be handling.

For instance, a diaphragm pump is great for viscous liquids and slurries. Understanding your specific requirements is crucial. Consider factors like flow rate and pressure range. The right diaphragm pump can improve efficiency and reduce costs.

However, you may encounter challenges when selecting a model. It's not just about specifications. Different applications may require unique features. Take time to research and reflect on your needs before making a decision. Focus on the two diaphragm pump options that best fit your situation. This will lead to better outcomes in the long run.

Understanding Diaphragm Pumps: Types and Applications

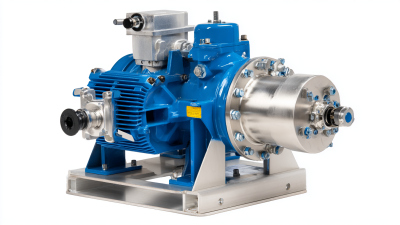

Diaphragm pumps are versatile tools used in various industries. They are well-known for their ability to handle different fluids, including corrosive ones. You can find diaphragm pumps in chemical processing, food and beverage production, and wastewater management. Understanding their types and applications can help you make better choices.

There are different types of diaphragm pumps. Air-operated ones are popular for their simplicity. Electric diaphragm pumps are convenient but may require more maintenance. Each type has its own set of advantages and drawbacks. It's essential to consider your specific needs and whether portability matters to you. For example, a lighter model may not be as robust as a heavier one.

When selecting a diaphragm pump, think about the fluid’s viscosity and temperature. Certain materials may not withstand high temperatures. You will need to check compatibility with your fluid type. That's where many choose wrong. They overlook vital details. It’s crucial to weigh these factors carefully to avoid costly mistakes in your pumping system.

How to Choose the Right Diaphragm Pump for Your Needs? - Understanding Diaphragm Pumps: Types and Applications

| Type | Application | Max Flow Rate (GPM) | Max Pressure (PSI) | Materials |

|---|---|---|---|---|

| Air-Operated Diaphragm Pump | Chemical Transfer | 0.5 - 80 | 0 - 120 | Polypropylene, Aluminum |

| Electric Diaphragm Pump | Water Treatment | 0.2 - 50 | 0 - 70 | Stainless Steel, PVC |

| Mini Diaphragm Pump | Ink Transfer | 0.1 - 10 | 0 - 30 | Silicone, Polyethylene |

| Solenoid Diaphragm Pump | Medical Applications | 0.2 - 5 | 0 - 25 | Polypropylene, Teflon |

| High Pressure Diaphragm Pump | Oil and Gas Industry | 0.5 - 15 | 0 - 250 | Titanium, Hastelloy |

Key Specifications to Consider When Choosing a Diaphragm Pump

When choosing a diaphragm pump, certain specifications matter significantly. Flow rate is a key metric. It determines how much fluid the pump can move within a specific time. If your application needs a high flow rate, select a pump that meets or exceeds your requirements. Consider startup and peak flow conditions as well.

Another crucial factor is the material of the diaphragm. Some materials handle corrosive fluids better. Others can withstand heat. Choosing the wrong material can lead to pump failure. Understanding the compatibility of the materials with your fluids is essential for performance.

Tips: Always analyze the environment where the pump operates. Dust, temperature changes, and humidity might affect the pump's efficiency. Don’t overlook the importance of maintenance. Regular checks help prevent unexpected downtimes. If unsure, seek professional advice on specific needs. It’s easy to make mistakes when under pressure. Reflect on past choices; they can guide future purchases.

Flow Rate and Pressure Requirements for Your Specific Use Case

Choosing the right diaphragm pump is crucial for optimal performance. It largely depends on your flow rate and pressure needs. These requirements may vary significantly based on your application. For example, a laboratory setup might require low flow rates at high pressure. In contrast, an agricultural application often demands higher flow rates but at lower pressures.

Understanding your specific use case is vital. Consider the fluid type you will be pumping. Viscosity affects both flow and pressure. A thicker fluid may require more power to achieve similar flow rates. If you ignore this factor, you might face performance issues. Additionally, fluctuations in pressure can lead to equipment damage, creating unnecessary costs.

Reflect on your installation setup. It should accommodate the pump's pressure capabilities. Sometimes, the ideal flow rate may not be feasible due to system constraints. An undersized pump won't meet your requirements. On the other hand, an oversized unit can waste energy. Always weigh these factors before making a decision. Every choice matters.

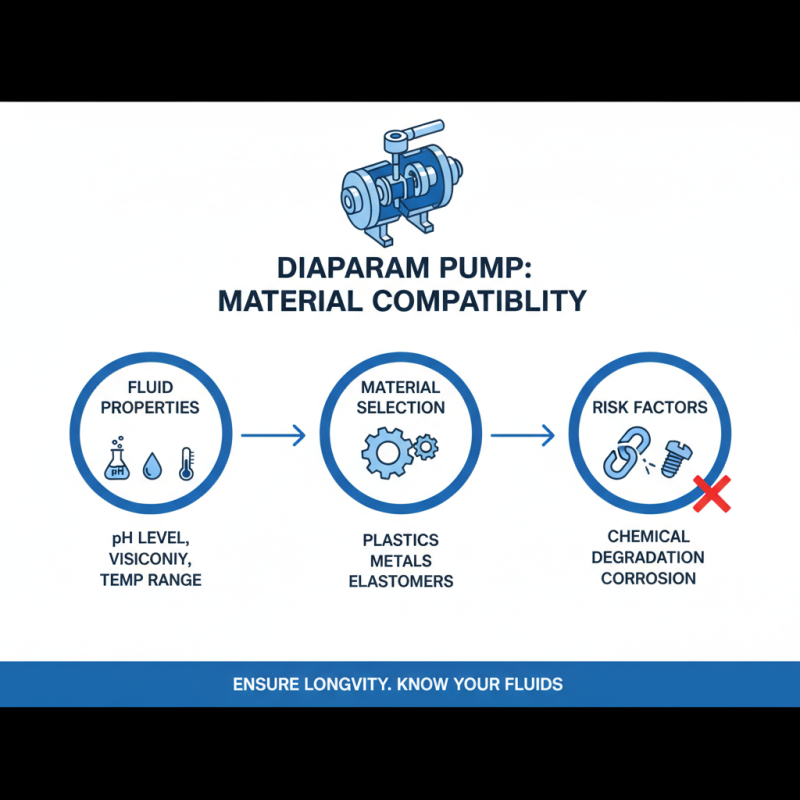

Material Compatibility in Diaphragm Pumps: Ensuring Longevity

When selecting a diaphragm pump, material compatibility is crucial for ensuring longevity. Different materials react uniquely to various fluids. For instance, certain plastics can degrade when exposed to strong chemicals. Metal components might corrode in humid environments. Knowing your fluid's properties is essential. Consider the pH level, viscosity, and temperature range.

Using incorrect materials can lead to pump failure. This not only affects productivity but also incurs extra costs. Sometimes, users overlook the importance of proper seals. A poor seal might cause leaks, impacting both performance and safety. Regular maintenance is essential to check for wear and tear. Understanding the limitations of your materials is vital. Choose wisely.

Maintenance and Performance Factors in Diaphragm Pump Selection

When selecting a diaphragm pump, maintenance is crucial. Regular checks can prevent costly breakdowns. For instance, inspect the diaphragm for wear and tear. A small crack can lead to significant issues. Regular maintenance enhances the pump's lifespan. It reduces the risk of leaks and inefficiencies, which can disrupt operations.

Performance is influenced by the application and environment. Different tasks require different specifications. Some pumps handle thicker liquids better than others. If you overlook this, you might face poor performance. Noise levels can also affect workplace conditions. A noisy pump can create an uncomfortable environment.

Consider ease of maintenance too. Some designs allow for quick diaphragm changes. Others may require specialized tools. If you choose a complex model, be prepared for challenges. It’s essential to weigh these factors. Balancing performance and ease of maintenance will lead to better choices.

Related Posts

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

-

How to Optimize Efficiency with High Pressure Pump Selection

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

What is a High Pressure Pump and How Does it Work Efficiently

-

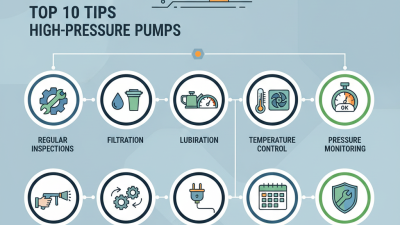

Top 10 Tips for Maintaining High Pressure Pumps Effectively