What is a High Pressure Pump and How Does it Work Efficiently

High pressure pumps play a crucial role in various industrial applications, from water jet cutting to hydraulic systems, where precise pressure control is paramount. According to a report by Allied Market Research, the global high pressure pump market is expected to reach $7.2 billion by 2027, exhibiting a CAGR of 4.5% from 2020 to 2027. This growth is driven by the increasing demand for efficient and reliable pumping solutions across sectors, including oil and gas, chemical processing, and waste management.

Efficient operation of a high pressure pump not only translates into energy savings but also enhances the overall performance of the systems they serve. The U.S. Department of Energy estimates that improving pump system efficiency can lead to energy savings of up to 20-50%, significantly reducing operational costs and environmental impact. By understanding the principles of how high pressure pumps function and the technology behind their operation, industries can better harness their capabilities, ensuring optimal performance and sustainability in demanding environments.

Understanding the Basics of High Pressure Pumps: Definition and Functionality

High pressure pumps play a crucial role in various industrial and engineering applications by providing the necessary force to move fluids efficiently. Defined by their ability to generate high pressure, these pumps operate on the principle of positive displacement, meaning they seal and displace a fixed volume of fluid with each cycle. This functionality is essential in sectors ranging from manufacturing to energy, where the movement of viscous liquids and gases is often involved.

The efficient operation of high pressure pumps relies on a thorough understanding of fluid dynamics and pump design. Key components, such as the impeller or diaphragm, are designed to enhance performance by minimizing energy loss and maximizing flow consistency. By applying principles derived from hydraulics, these pumps can adapt to varying fluid properties, making them indispensable for tasks requiring precision and reliability. As industries continue to evolve, the advancements in high pressure pump technology promise to improve efficiency and safety protocols across applications.

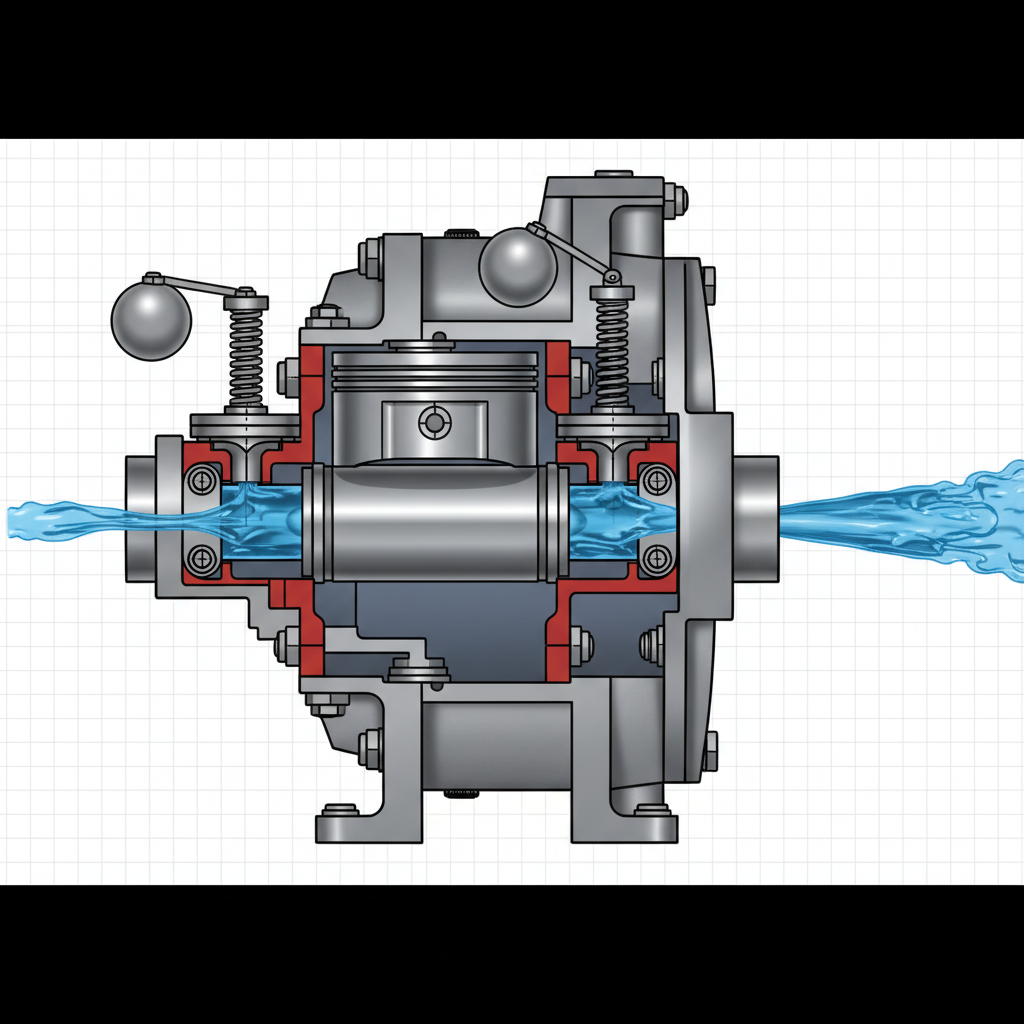

The Mechanisms Behind High Pressure Pump Operation: Key Components Explained

High pressure pumps are essential devices that operate on specific mechanisms designed to generate and maintain high fluid pressures. The fundamental components involved in their operation include the pump casing, piston or diaphragm, inlet and outlet valves, and hydraulic fluid. The casing provides a robust structure to contain the hydraulic forces, while the piston or diaphragm creates the necessary pressure difference to draw fluid into the pump and push it out under high pressure.

The inlet and outlet valves play a crucial role in maintaining the flow of fluid within the pump. The inlet valve ensures that fluid is drawn into the chamber when the piston descends, while the outlet valve closes off the chamber to build pressure during the upward stroke. Additionally, the efficiency of a high pressure pump is significantly influenced by the choice of hydraulic fluid, which affects viscosity and flow characteristics. Together, these components must be precisely engineered to work in harmony, ensuring optimal performance and energy efficiency during operation, whether in industrial applications or hydraulic systems.

Factors Influencing the Efficiency of High Pressure Pumps in Various Applications

High pressure pumps play a crucial role in various applications across industries, and their efficiency is influenced by several key factors. One of the primary factors is the design and material of the pump. Pumps constructed from high-quality materials that resist wear and corrosion tend to perform better and last longer. Additionally, the pump's design must be optimized for the specific application it serves, ensuring that it operates efficiently under varying conditions.

Another significant factor impacting the efficiency of high pressure pumps is the drive system used. Variable Frequency Drives (VFDs) can enhance pump efficiency by allowing operators to adjust the pump's speed according to the demand, which helps in conserving energy and reducing wear on components. As the VFD market is projected to grow steadily, more industries are likely to adopt this technology to improve their pump systems.

Tips: When selecting a high pressure pump, consider investing in models that offer compatibility with VFDs. This can lead to significant energy savings and improve overall system performance. Additionally, regular maintenance and timely replacements of worn-out parts can prolong the life of your pump and maintain efficiency. Always monitor the application requirements closely to ensure your pump operates within its optimal range.

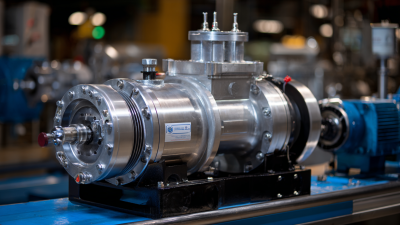

Innovative Technologies Enhancing High Pressure Pump Performance for 2025

Innovative technologies are transforming the landscape of high pressure pumps, paving the way for enhanced efficiency and performance by 2025. One of the most significant advancements is the integration of smart sensors and automation systems. These technologies enable real-time monitoring of pump conditions, allowing for proactive adjustments that optimize performance and minimize energy consumption. For instance, predictive maintenance algorithms can forecast potential failures, reducing downtime and maintenance costs, thereby extending the lifespan of the pumps.

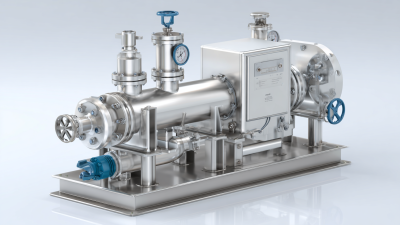

Additionally, advancements in materials science are leading to the development of more durable and lightweight pump components. High-strength alloys and advanced polymers can withstand extreme pressure and temperature variations while reducing the overall weight of the pump. This not only improves the efficiency of the pumps by lowering the energy required for operation but also enhances their adaptability in various industrial applications. As these innovative technologies continue to evolve, we can expect high pressure pumps to become significantly more efficient, reliable, and sustainable by 2025.

What is a High Pressure Pump and How Does it Work Efficiently - Innovative Technologies Enhancing High Pressure Pump Performance for 2025

| Dimension | Value | Description |

|---|---|---|

| Max Pressure (bar) | 250 | The maximum pressure that the pump can achieve. |

| Flow Rate (L/min) | 100 | The amount of fluid that can be pumped per minute. |

| Power Consumption (kW) | 15 | The energy required for the pump to operate efficiently. |

| Material | Stainless Steel | The primary material used in the construction of the pump. |

| Efficiency (%) | 85 | The ratio of useful work output to the total energy input. |

| Maintenance Interval (months) | 6 | Recommended time frame for regular maintenance. |

Maintenance Tips for Prolonging the Lifespan of High Pressure Pumps and Ensuring Efficiency

High pressure pumps are remarkable machines designed to deliver fluids at significant pressures, making them essential in various industries such as construction, manufacturing, and oil extraction. To ensure optimal performance and longevity of these pumps, regular maintenance is crucial. A routine inspection should be carried out to check for leaks, worn seals, and unusual vibrations, which can indicate potential issues. Ensuring that the pump operates within its designed pressure limits can prevent unnecessary wear and tear.

Additionally, it's important to keep the pump clean and free from debris. Contaminants can lead to blockages and damage, which ultimately hinder the pump's efficiency. Lubricating the moving parts with the recommended oil can enhance performance and prevent overheating. Regularly replacing filters and ensuring that hoses and fittings are secured will also contribute to maintaining high pressure pump efficiency. By adhering to these maintenance tips, operators can prolong the lifespan of their pumps while ensuring they operate at peak efficiency.

High Pressure Pump Efficiency and Maintenance Tips

Related Posts

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

How to Optimize Efficiency with High Pressure Pump Selection

-

2025 Top 10 High Pressure Pump Innovations for Industrial Applications

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry

-

Exploring Innovative Chemical Pump Alternatives for Industrial Applications

-

Top 10 Best 12 Volt Pumps for Every Need: Ultimate Buying Guide