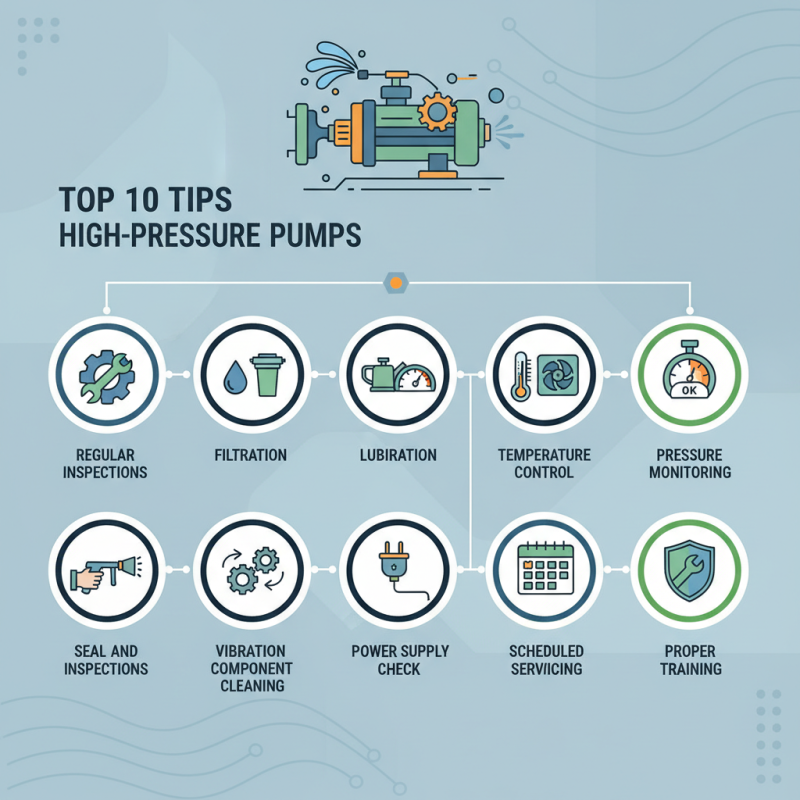

Top 10 Tips for Maintaining High Pressure Pumps Effectively

In the field of industrial machinery, maintaining high pressure pumps is crucial for ensuring optimal performance and longevity. According to John Smith, a leading expert in fluid dynamics and high pressure pump technology, "Regular maintenance is the key to preventing failures and maximizing the efficiency of high pressure pumps." His insights underline the importance of proactive care and attention to these vital components in various applications, from manufacturing to energy production.

High pressure pumps operate under extreme conditions, making their upkeep essential for sustained operation. Neglecting maintenance can lead to costly downtime and repairs, which can significantly impact productivity. Therefore, understanding the best practices for maintaining high pressure pumps not only enhances their reliability but also safeguards the investment made in these intricate systems.

In this article, we will explore the top 10 tips for effectively maintaining high pressure pumps. By implementing these strategies, operators can ensure their pumps function efficiently, minimize operational disruptions, and extend the lifespan of their equipment. Whether you are a seasoned professional or new to the industry, these insights will provide valuable guidance to optimize your high pressure pump management.

Understanding High Pressure Pumps: Functionality and Applications

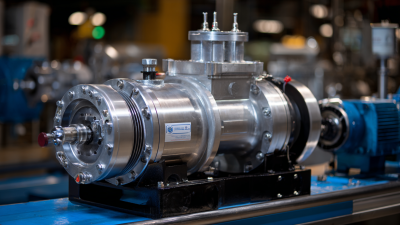

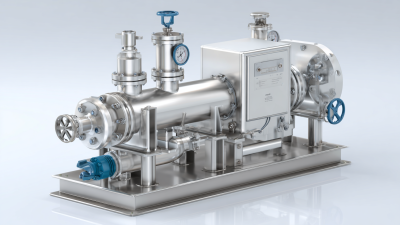

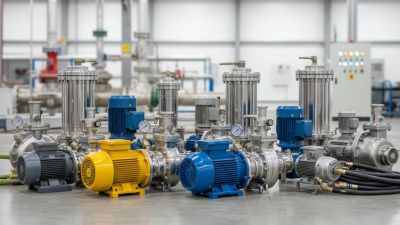

High pressure pumps are critical components in various industrial applications, ranging from water jet cutting to oil and gas extraction. These pumps are designed to handle fluids at pressures exceeding 1,500 psi, making them indispensable in operations that require precision and efficiency. According to a report by the Global Market Insights, the high pressure pump market is projected to reach USD 3.2 billion by 2026, driven by the growing demand in sectors like manufacturing and energy production.

Understanding the functionality of high pressure pumps is essential for their effective utilization. These pumps operate by converting mechanical energy into hydraulic energy, allowing for the movement of fluids at high velocities. Applications include cleaning, surface preparation, and material processing, which are critical in industries such as construction and automotive manufacturing. A study by the American Society of Mechanical Engineers (ASME) highlights that utilizing high pressure pumps can lead to a 25% increase in process efficiency in fluid transportation systems, underscoring their importance in operational settings. As industries continue to adopt automation and sophisticated fluid management systems, the role of high pressure pumps will only become more pivotal.

Key Maintenance Strategies to Extend the Lifespan of High Pressure Pumps

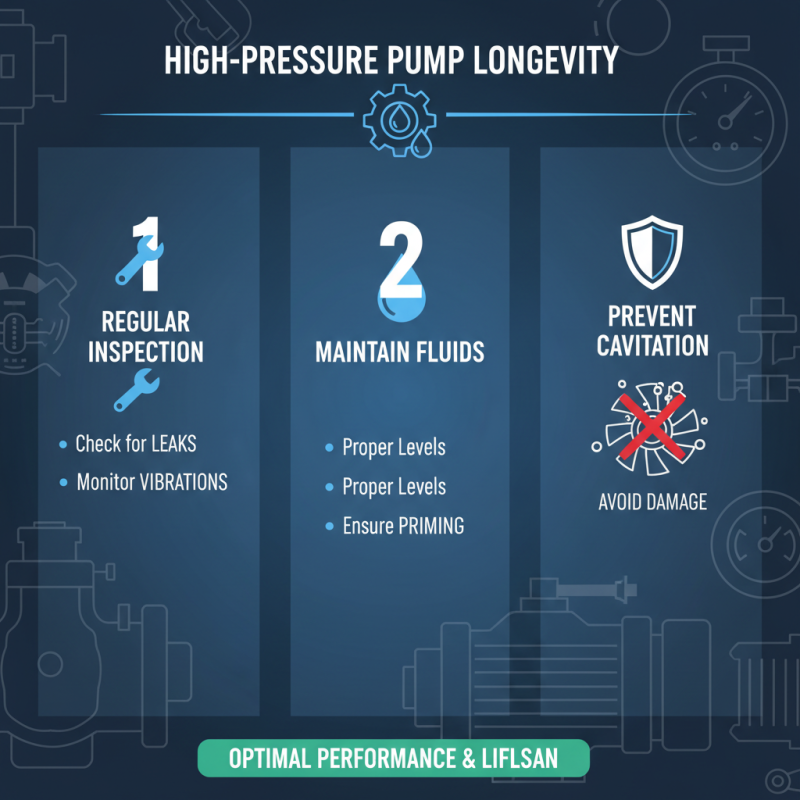

High pressure pumps are vital components in numerous industrial applications, and proper maintenance is essential to ensure their optimal performance and longevity. One of the key strategies for extending the lifespan of these pumps involves regular inspection and monitoring. Operators should frequently check for signs of wear and tear, such as leaks or unusual vibrations, to catch potential issues early. Maintaining proper fluid levels and ensuring the pump is primed can prevent cavitation, a common problem that can severely damage pump components.

Another important maintenance strategy is the implementation of a routine cleaning schedule. High pressure pumps can accumulate sediments and debris, which can impact their efficiency and functionality. Cleaning the pump’s internals and filters on a regular basis helps to prevent clogging and reduces the risk of malfunctions. Additionally, using the correct lubricants and following recommended lubrication schedules is crucial for reducing friction and wear on moving parts. These practices, combined with operator training on best practices for high pressure pump use, create a comprehensive maintenance plan that significantly extends pump operational life.

Common Issues and Troubleshooting Techniques for High Pressure Pumps

High pressure pumps are essential for various industrial applications, but they can encounter common issues that may hinder their performance.

One prevalent problem is cavitation, which occurs when the pressure in the pump falls below the vapor pressure of the liquid being pumped. This can lead to noise, vibration, and even damage to the impeller. To troubleshoot cavitation, ensure that the suction line is properly designed and maintained, and check for any obstructions that could restrict flow. Additionally, maintaining optimal operational conditions, such as temperature and pressure, can help minimize the risk of cavitation.

Another common issue is seal failure, which often results from wear and tear or inadequate lubrication. When seals fail, leaks can occur, leading to significant losses in efficiency and potential damage to the pump components. It is essential to regularly inspect seals for signs of wear and replace them as necessary.

Proper lubrication and monitoring of operating temperatures can help prolong the life of seals. Implementing a routine maintenance schedule that includes these checks can significantly reduce downtime and enhance the reliability of high pressure pumps.

Importance of Regular Inspections and How They Impact Efficiency

Regular inspections of high pressure pumps are crucial for maintaining their efficiency and prolonging their lifespan. During these inspections, potential issues such as wear and tear, leaks, and other operational anomalies can be identified and addressed before they escalate into major problems. This proactive approach not only enhances the reliability of the pumps but also minimizes downtime, ensuring that systems remain operational and perform at peak effectiveness.

To maintain high pressure pumps effectively, consider implementing a routine inspection schedule. Conduct visual checks for any signs of corrosion or damage, ensuring seals and fittings are intact. Another essential tip is to monitor the pump’s performance metrics closely. Consistent tracking of pressure levels, flow rates, and energy consumption can help detect any irregularities early on. Additionally, keeping a detailed maintenance log can provide insight into the pump’s history and inform future servicing needs.

Furthermore, investing in staff training on proper operating procedures can greatly impact pump efficiency. Educated operators are better equipped to recognize abnormal behaviors and respond promptly. By prioritizing regular inspections and maintenance practices, you can significantly reduce operational costs and enhance the overall effectiveness of high pressure pumps.

Impact of Operating Environment on High Pressure Pump Performance

The operating environment plays a crucial role in the performance and longevity of high-pressure pumps. Factors such as temperature, humidity, and the presence of corrosive substances can significantly impact pump efficiency. According to a report by the Hydraulic Institute, about 50% of pump failures are attributed to suboptimal operating conditions. For instance, high ambient temperatures can reduce lubrication effectiveness, while excessive humidity can lead to corrosion and rust formation on pump components, subsequently decreasing performance.

Furthermore, the quality of the fluids being pumped is also critical. A study by the American Society of Mechanical Engineers indicates that fluids containing abrasive particles can reduce the lifespan of high-pressure pumps by as much as 40%. Regular monitoring of the operating environment, including the cleanliness of the working area and the type of fluids used, is essential for maintaining pump efficiency. Implementing proper filtration systems and environmental controls can mitigate these risks, leading to improved performance and reduced downtime. By prioritizing these environmental factors, operators can ensure optimal functioning and extend the life of their high-pressure pump systems.

Impact of Operating Environment on High Pressure Pump Performance

This chart illustrates the relationship between different operating environments and the efficiency of high pressure pumps. The data is based on average performance metrics across various conditions.

Related Posts

-

How to Optimize Efficiency with High Pressure Pump Selection

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

What is a High Pressure Pump and How Does it Work Efficiently

-

10 Best High Pressure Pumps for Efficient Fluid Transfer in 2023

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China

-

2025 Top 10 High Pressure Pump Innovations for Industrial Applications