2025 Top 10 High Pressure Pump Innovations for Industrial Applications

In the rapidly evolving landscape of industrial applications, the role of high pressure pumps has become increasingly vital. As industries strive for greater efficiency and sustainability, technological innovations in high pressure pump design and functionality have emerged as key drivers of progress. This article delves into the top 10 high pressure pump innovations expected to revolutionize industrial operations by 2025, showcasing advancements that not only enhance performance but also address environmental concerns.

From smart sensors that enable real-time monitoring to energy-efficient designs that reduce operational costs, these innovations reflect the ongoing transformation within the sector. Companies are continuously seeking solutions that combine power and precision, which allows them to tackle demanding applications across various fields such as oil and gas, chemical processing, and food production. By embracing these forward-thinking technologies, industries can improve productivity while minimizing their environmental footprint, thus setting a new standard in high pressure pump applications.

Join us as we explore these cutting-edge solutions and provide valuable tips for integrating them into your operations for maximum benefit.

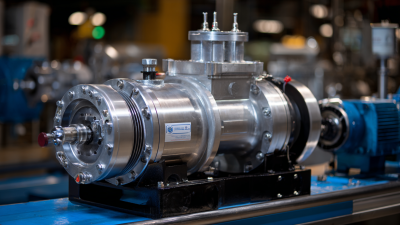

Revolutionary Materials Enhancing High Pressure Pump Durability

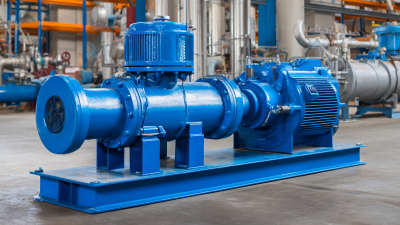

Advanced Pump Configurations Enhancing Versatility in Industrial Use

2025 Top 10 High Pressure Pump Innovations for Industrial Applications

Smart Technologies for Real-Time Monitoring and Control of Pumps

The advancement of smart technologies for real-time monitoring and control of high-pressure pumps is revolutionizing industrial applications. According to a recent report by MarketsandMarkets, the global smart pump market is projected to grow from $2.5 billion in 2021 to $5.8 billion by 2026, reflecting a significant compound annual growth rate (CAGR) of 18.1%. This rapid growth is driven by the increasing demand for efficiency and reliability, particularly in sectors such as oil and gas, water and wastewater management, and chemical processing.

Real-time monitoring capabilities enable operators to collect and analyze data pertaining to pump performance and operational conditions. For instance, integrating Internet of Things (IoT) sensors allows for the continuous tracking of parameters like pressure, flow rate, and temperature. A report by the International Water Association indicates that utilizing smart technologies can reduce operational costs by up to 20% and enhance energy efficiency by 15%. Moreover, predictive maintenance powered by advanced analytics minimizes downtime, significantly benefiting industries that rely on high-pressure pumps for critical processes, ensuring uninterrupted operations and improved safety standards.

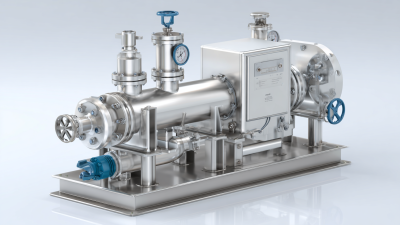

Energy-Efficient Designs Leading the Next Generation of Pumps

As industries evolve, energy-efficient designs are becoming paramount in the development of high-pressure pumps. In fact, according to a report by the Global Pump Industry, energy-efficient pumps can reduce overall energy consumption by up to 30%, leading to significant cost savings in long-term operations. This innovative approach not only helps companies decrease their carbon footprint but also addresses the growing demand for sustainable industrial practices.

The 2025 landscape of high-pressure pump technologies will likely showcase a range of advancements tailored for enhanced efficiency. For instance, variable frequency drives (VFDs) are being integrated more frequently, allowing for precise control over pump speed and operation. A study from the International Energy Agency highlights that implementing such technologies could save global industries approximately $200 billion annually in energy costs. As manufacturers prioritize the development of energy-centric designs, we can expect these innovations to redefine the standards for performance and sustainability in industrial applications.

Innovative Sealing Solutions for Leak Prevention and Maintenance

As industrial applications continue to evolve, the need for effective sealing solutions becomes increasingly critical. Innovative sealing technologies are essential for high-pressure pumps, as they help prevent leaks that can lead to costly downtime and maintenance issues. Among the advancements in sealing solutions, materials like PTFE and elastomers are being engineered to withstand extreme pressures and temperatures, offering enhanced durability and longevity. These materials are designed to create a reliable barrier, ensuring that the integrity of the system is maintained even under the most challenging conditions.

In addition to utilizing advanced materials, the integration of smart sealing solutions is gaining traction in the industry. These systems incorporate sensors and monitoring technology to provide real-time data on seal performance and wear. By enabling predictive maintenance strategies, operators can address potential issues before they lead to failures, optimizing both productivity and safety. This innovative approach not only enhances the reliability of high-pressure pumps but also contributes to cost savings in maintenance and operation, making them an indispensable part of modern industrial applications.

Advanced Pump Configurations Enhancing Versatility in Industrial Use

The industrial pump market is evolving rapidly, driven by the demand for efficiency and versatility. According to a recent report by MarketsandMarkets, the global industrial pump market is projected to grow from $60 billion in 2020 to $80 billion by 2025, highlighting the increasing importance of advanced pump configurations. Innovations such as multi-stage pumps and variable frequency drives are enhancing operational efficiency, allowing for greater adaptability across various industrial applications, from chemical processing to water treatment.

One of the most significant advancements is the integration of smart technologies in pump design. These intelligent pumps, equipped with IoT capabilities, provide real-time monitoring and predictive maintenance alerts, significantly reducing downtime and operational costs. A report by Global Market Insights indicates that smart pump technology is expected to witness a compound annual growth rate (CAGR) of 7% through 2025. This growth underscores the industry's shift towards smarter, more versatile solutions that cater to an array of challenging environments while optimizing performance and energy consumption.

2025 Top 10 High Pressure Pump Innovations for Industrial Applications

| Innovation | Type | Max Pressure (psi) | Flow Rate (GPM) | Efficiency (%) |

|---|---|---|---|---|

| Smart Control Systems | Electric | 5000 | 100 | 95 |

| Variable Displacement Mechanisms | Hydraulic | 7000 | 75 | 92 |

| Ceramic Coating Technology | Positive Displacement | 6000 | 50 | 90 |

| Integrated Energy Recovery | Centifugal | 4000 | 120 | 96 |

| Remote Monitoring Capabilities | Electric | 5000 | 90 | 91 |

| Modular Pump Designs | Submersible | 3500 | 60 | 89 |

| Enhanced Sealing Technologies | Diaphragm | 8000 | 40 | 94 |

| Advanced Material Compositions | Piston | 9000 | 55 | 97 |

| Hybrid Drive Systems | Electric & Hydraulic | 7500 | 100 | 93 |

| Artificial Intelligence Integration | Electric | 5000 | 110 | 95 |

Related Posts

-

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

-

How to Optimize Efficiency with High Pressure Pump Selection

-

Exploring High Pressure Diaphragm Pump Innovations at the 138th Canton Fair 2025 in China

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

What is a Small Submersible Pump? Key Features, Benefits, and Industry Insights for Efficient Water Management

-

The Ultimate Guide to Choosing the Right Electric Pumps for Your Home and Garden