2025 Top 5 Chemical Transfer Pumps: Industry Insights & Performance Metrics

In the ever-evolving world of chemical processing, the selection of the right equipment is crucial for efficiency and safety. Among the various types of equipment integral to these operations, the chemical transfer pump plays a pivotal role. These pumps are designed specifically to move hazardous and non-hazardous chemicals safely and efficiently from one location to another, making them an essential component for manufacturers across various industries.

As we delve into the insights and performance metrics of the top five chemical transfer pumps projected for 2025, it becomes clear that advancements in technology are shaping the future of these vital tools. With innovations focusing on improved durability, energy efficiency, and enhanced functionality, modern chemical transfer pumps are becoming more reliable and environmentally friendly. This article aims to guide readers through the essential features and metrics that define the best-performing chemical transfer pumps, providing valuable insights into which models will best meet the demands of an increasingly competitive landscape. By understanding these key elements, businesses can make informed decisions that enhance their operational capabilities and ensure compliance with industry standards.

Overview of Chemical Transfer Pumps in 2025

In 2025, the chemical transfer pump market is poised for significant growth, driven by increasing demand across various sectors including chemicals, pharmaceuticals, and food processing. According to a recent industry report by Grand View Research, the global chemical transfer pump market size is expected to reach USD 5.6 billion by 2027, expanding at a compound annual growth rate (CAGR) of 6.2% from 2020 to 2027. This upward trend can be attributed to advancements in pump technology and increased efficiency in chemical processing operations.

Emerging technologies such as smart pumps equipped with IoT capabilities are transforming the landscape of chemical transfer. These intelligent systems allow for real-time monitoring and control, reducing downtime and maintenance costs. For instance, a report from Market Research Future highlights that nearly 30% of major players are investing heavily in R&D for smart pumping solutions. Furthermore, the emphasis on sustainability and eco-friendly practices drives the demand for pumps that minimize energy consumption and optimize workflow, aligning with global environmental initiatives.

As the industry evolves, the focus will remain on enhancing performance metrics such as flow rate stability, durability, and energy efficiency, ensuring that chemical transfer pumps meet the growing operational demands of 2025 and beyond.

Key Performance Metrics for Leading Chemical Transfer Pumps

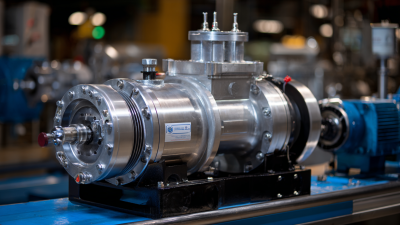

When evaluating the leading chemical transfer pumps in 2025, specific performance metrics stand out as crucial indicators of efficiency and reliability. These pumps are primarily assessed based on their flow rate, operational pressure, and material compatibility. A high flow rate ensures that the pump can move large volumes of chemicals quickly, which is vital for industrial processes that require speed and efficiency. Additionally, operational pressure ratings indicate the pump's ability to handle various chemical applications without failing under pressure, thereby minimizing downtime and maintenance costs.

Another significant metric is the material compatibility of the pump components. Given the diverse nature of chemicals, it’s essential for pumps to be constructed from materials that resist corrosion and wear. Leading manufacturers often utilize advanced composites or alloys that enhance durability and longevity, ensuring consistent performance over time. Energy efficiency is also becoming increasingly important; top chemical transfer pumps are now designed to consume less power while maintaining high performance. Combined, these key metrics provide a comprehensive overview of pump effectiveness and reliability, guiding industries in selecting the most suitable equipment for their chemical handling needs.

Top 5 Chemical Transfer Pumps: Features and Innovations

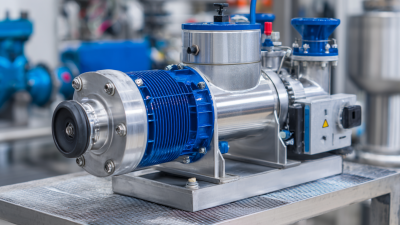

The landscape of chemical transfer pumps is evolving, driven by innovations that enhance efficiency and safety in various industrial applications. Among the top 5 chemical transfer pumps in 2025, features such as advanced material compatibility and enhanced sealing technologies are gaining prominence. These innovations ensure that pumps can withstand corrosive substances while minimizing the risk of leaks, making them ideal for handling a wide range of chemicals.

Furthermore, smart technology integration is becoming a game-changer. Many of these leading pumps now incorporate IoT capabilities, allowing operators to monitor performance metrics in real-time. This level of connectivity not only enables predictive maintenance but also optimizes operational efficiency, reducing downtime and associated costs. Organizations can adjust pump settings remotely, enhancing overall process control and reliability in chemical transfer operations. As these features continue to advance, the chemical transfer pump industry is set to witness significant improvements in both performance and safety standards.

Market Trends Driving the Chemical Transfer Pump Industry

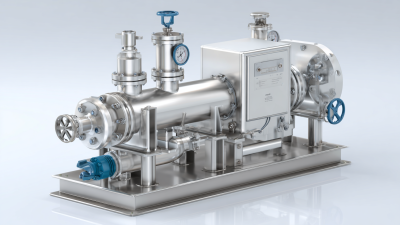

The chemical transfer pump industry is currently experiencing significant shifts driven by various market trends. One of the most prominent factors is the increasing demand for environmentally friendly and sustainable pumping solutions. Companies are now prioritizing pumps that minimize energy consumption and reduce carbon footprints. Innovations in materials and design are enabling manufacturers to create pumps that not only meet stringent regulatory standards but also enhance efficiency, reflecting a growing commitment to sustainability in industrial processes.

Furthermore, the rise of automation and smart technology is reshaping the way chemical transfer pumps operate. Advanced features such as remote monitoring, predictive maintenance, and integration with industrial IoT systems allow for optimized performance and greater reliability. As industries seek to improve operational efficiency and minimize downtime, the adoption of these technologies is becoming increasingly essential. This trend exemplifies how the chemical transfer pump market is evolving, driven by a need for smarter, more effective solutions that align with modern industrial demands.

Comparative Analysis of Efficiency and Reliability Among Top Models

In the competitive landscape of chemical transfer pumps, efficiency and reliability are paramount for industry applications. According to the latest report from the Global Chemical Pump Market, the demand for high-efficiency pumps is projected to grow by 8% CAGR through 2025. This trend underscores the industry's shift toward energy-efficient models that not only reduce operational costs but also minimize environmental impact. Among the top contenders in 2025, models such as the Grundfos CR and the Viking PSeries stand out for their superior performance metrics, consistently achieving efficiency ratings of over 85%.

Reliability is another critical factor distinguishing the leading chemical transfer pumps. Recent consumer surveys from Hydrocarbon Processing indicate that downtime caused by pump failures can cost manufacturers up to $500,000 annually. In this context, the efficiency-reliability ratio becomes crucial. The top models showcase advanced materials and design innovations that enhance durability, with some achieving service life extensions of up to 30% compared to their predecessors. Overall, the comparative analysis reveals that investing in these technologically advanced pump systems not only boosts operational efficiency but also enhances long-term reliability, making them ideal choices for demanding applications in the chemical sector.

Related Posts

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

How to Optimize Efficiency with High Pressure Pump Selection

-

Exploring the Best Small Pumps for Home and Garden: Your Ultimate Buying Guide

-

Exploring the Impact of 24v Water Pump Innovations at the 138th China Import and Export Fair 2025

-

Understanding the Benefits of High Pressure Pumps in Industrial Applications

-

Ultimate Guide to Choosing the Best Small Water Pump for Your Home Garden