Top 10 Industrial Pumps: Choosing the Right One for Your Needs

In the ever-evolving world of industrial processes, the selection of the right equipment becomes paramount for operational efficiency and cost-effectiveness. Industrial pumps play a critical role in various sectors, including oil and gas, water treatment, and chemical manufacturing. According to a recent report by the Global Market Insights Research Group, the industrial pumps market is projected to exceed $80 billion by 2026, driven by advancements in technologies and the rising demand for more efficient fluid transfer solutions.

Experts emphasize the importance of understanding the specific requirements of your application when choosing the right pump. Dr. John Smith, a renowned expert in fluid dynamics and the industrial pump sector, states, "Selecting the appropriate industrial pump not only affects the overall productivity of operations but also significantly influences long-term sustainability and maintenance costs." This insight highlights how the complexities of fluid handling necessitate a thoughtful approach to pump selection, ensuring compatibility with varying viscosity, temperature, and pressure conditions.

As we delve into the top ten industrial pumps, it is essential to consider factors such as performance, durability, and the specific needs of your operations. Making an informed decision can lead to enhanced efficiency, reduced downtime, and improved outcomes across industrial applications.

Types of Industrial Pumps and Their Applications

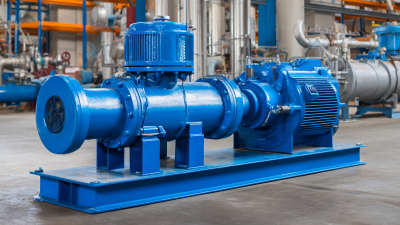

Industrial pumps are essential components in various sectors, each designed for specific applications. The most common types include centrifugal pumps, positive displacement pumps, diaphragm pumps, and peristaltic pumps. Centrifugal pumps utilize rotational energy to move fluids, making them ideal for low-viscosity liquids in water supply, chemical processing, and HVAC applications. They are widely preferred for their efficiency and simplicity, especially in applications requiring a constant flow rate.

In contrast, positive displacement pumps are more versatile when dealing with high-viscosity fluids. They work by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them suitable for moving thick slurries, oils, and other dense materials. Diaphragm pumps are particularly useful in applications where the fluid must remain uncontaminated, such as in food processing and pharmaceuticals, due to their ability to isolate the fluid from the drive mechanism. Lastly, peristaltic pumps operate by compressing a flexible tube, making them ideal for precise fluid handling in laboratory settings and wastewater treatment, as they can manage abrasive and corrosive fluids with minimal wear.

When selecting the right pump, it's crucial to consider factors such as the nature of the fluid, flow rate, and system pressure requirements. Understanding the strengths and limitations of each pump type can significantly impact efficiency and operational costs in industrial processes.

Key Factors to Consider When Choosing an Industrial Pump

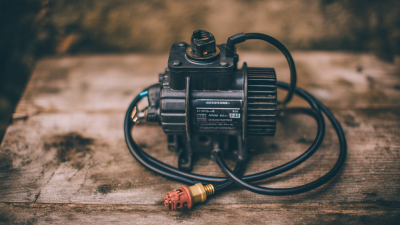

When choosing an industrial pump, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, understanding the fluid being transported is crucial. The viscosity, temperature, and chemical composition of the fluid can dictate the type of pump needed. For instance, corrosive fluids may require pumps made from specific materials that resist degradation while viscous fluids could necessitate pumps designed to handle higher flow rates without compromising pressure.

Another critical factor is the required flow rate and pressure. Each application will have specific demands, and knowing the required specifications is essential. Selecting a pump that can maintain the necessary flow and pressure will directly influence the effectiveness of the system. Additionally, evaluating the installation environment can impact the choice; factors like space limitations, noise levels, and accessibility for maintenance are all important considerations that can affect the overall functionality of the pump. Proper assessment of these criteria can lead to selecting a pump that not only meets operational needs but also optimizes performance and longevity in the industrial setting.

Top 10 Industrial Pumps: Choosing the Right One for Your Needs

| Pump Type | Flow Rate (GPM) | Head Pressure (ft) | Power (HP) | Application | Material |

|---|---|---|---|---|---|

| Centrifugal Pump | 50 | 150 | 5 | General Fluid Transfer | Cast Iron |

| Diaphragm Pump | 30 | 80 | 3 | Chemical Transfer | Plastic |

| Gear Pump | 20 | 100 | 2 | Oil Transfer | Aluminum |

| Submersible Pump | 75 | 90 | 7 | Wastewater Removal | Stainless Steel |

| Piston Pump | 40 | 120 | 4 | High-Pressure Applications | Steel |

| Peristaltic Pump | 10 | 50 | 1 | Food Processing | Rubber |

| Screw Pump | 60 | 200 | 6 | Heavy Oil Transfer | Bronze |

| Lobe Pump | 55 | 110 | 5.5 | Viscous Fluid Transfer | Stainless Steel |

| Vacuum Pump | 15 | 70 | 2 | Packaging Industry | Aluminum |

| Magnetic Drive Pump | 25 | 40 | 3 | Corrosive Liquid Transfer | Composite |

Comparative Analysis of the Top 10 Industrial Pumps Available

When selecting an industrial pump, it's crucial to consider the specific application and operational requirements. A comparative analysis of the top 10 industrial pumps reveals significant distinctions in efficiency, flow rates, and pressure capabilities. According to a recent report by Frost & Sullivan, the industrial pump market is projected to grow at a CAGR of 4.3% through 2026, highlighting the increasing demand for advanced pumping solutions across various sectors.

For example, centrifugal pumps are often favored for their high flow rates and efficiency, making them ideal for water and wastewater applications, while positive displacement pumps are preferred in industries requiring precise fluid measurement and handling.

Tip: When evaluating pumps, pay attention to the total cost of ownership, which includes not only the initial purchase price but also maintenance and energy consumption over the pump's lifecycle. Efficient models can significantly reduce operational costs, providing a substantial return on investment.

Moreover, it's essential to assess the material compatibility of the pump with the fluid being handled, as improper material can lead to premature wear or failure. According to a study by the Hydraulic Institute, improper selection of pump materials accounts for up to 15% of pump failures in industrial applications. Understanding the fluid characteristics, such as viscosity and corrosiveness, will ensure optimal performance and longevity of the pumping system.

Tip: Always consult engineering resources or guidelines that outline best practices for pump selection and maintenance to minimize unexpected downtime and enhance system reliability.

Maintenance Tips for Optimal Performance of Industrial Pumps

Maintaining industrial pumps is essential for ensuring their optimal performance and longevity. Regular inspections should be conducted to identify any signs of wear or damage, such as leaks or unusual noises. Checking for proper alignment and securing loose fittings can prevent operational issues that may lead to costly downtime. Additionally, it’s important to monitor the pump’s operating parameters, including flow rate and pressure, to ensure they remain within the manufacturer’s recommended ranges.

Another key aspect of maintenance is the lubrication of moving parts. Using the correct type and amount of lubricant not only reduces friction but also minimizes wear and tear, ultimately extending the lifespan of the pump. Filter elements should be inspected and replaced as necessary to avoid clogs that can impair performance. Lastly, establishing a routine maintenance schedule will help ensure that all tasks are performed consistently, allowing for the early detection of problems before they escalate. This proactive approach will contribute to the reliability and efficiency of industrial pumps in various applications.

Cost Considerations and Budgeting for Industrial Pump Purchase

When budgeting for industrial pump purchases, it's essential to consider both initial costs and long-term operational expenses. According to industry reports, the overall cost of owning an industrial pump is significantly influenced by power consumption, maintenance requirements, and the materials used in its construction. For example, a high-efficiency pump might come with a higher upfront price but reduce energy costs by up to 30% over time, leading to substantial savings.

Tip: Always calculate the total cost of ownership (TCO), which includes purchase price, installation, maintenance, and energy costs. This calculation will help you make better-informed decisions that align with your budget and operational needs.

Additionally, it's wise to account for potential financial fluctuations in the market. Industrial pump prices can vary based on raw material costs and technological advancements. An insightful strategy is to stay updated on market trends by reviewing industry reports and forecasts regularly. This will help in making timely purchasing decisions and potentially capitalizing on cost-saving opportunities.

Tip: Set aside a contingency fund of about 10-15% of your total budget for unexpected expenses or necessary upgrades, ensuring you are prepared for all eventualities in your pump investment.

Related Posts

-

Ultimate Guide to Choosing the Right Water Pump for Your Needs

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success

-

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

-

Unleashing Efficiency: How High-Pressure Water Pumps Transform Agricultural Irrigation Systems

-

10 Essential Tips for Choosing the Best Electric Transfer Pump for Your Needs

-

Top 10 Best 12 Volt Pumps for Every Need: Ultimate Buying Guide